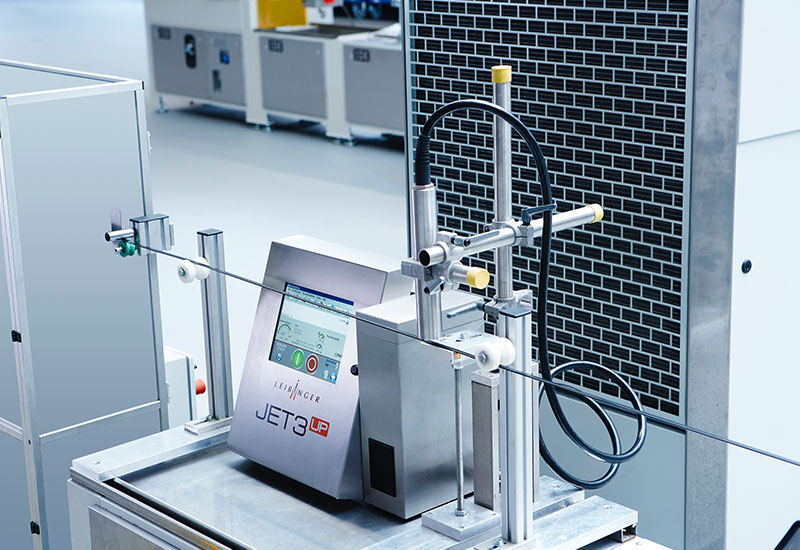

The advanced, feature-rich printer for complex and challenging applications

More complex production environments require more sophisticated coding and marking solultions – and they don’t come any smarter or more powerful than the JET3up. It prints up to 5 lines. Performs up to 403 m/min, and comes with a rich array of features and flexible options. 100% German-made with a global reputation for reliability, the JET3up is easy to use and employs LEIBINGER’s unique Sealtronic print head technology that eliminates the need for cleaning or rinsing. The JET3up will help you rise to any industrial coding or marking challenge, and keep production lines running with maximum uptime.

JET3up at a glance

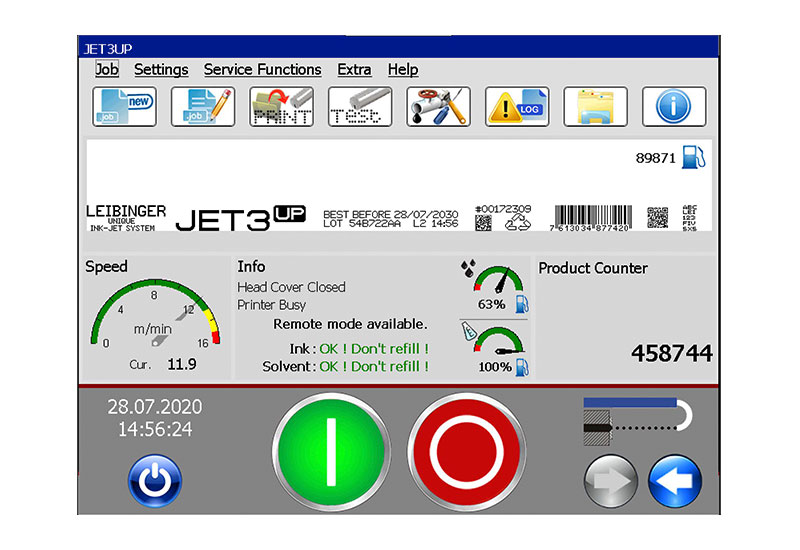

- Over 800 user-friendly functions

- Up to 5-line texts can be printed at up to 403 m/min

- Sealtronic print head technology rids clogging and frequent head cleaning

- Non-contact marking

- Height of the fonts: 5-32 drops

- Windows-based touchscreen display for convenient operation

- Suitable as a food grade printer and many more

- Multiple inks available

- All software updates included

Print on:

Glass

Carton

Film

Foils

Plastics

Metal

Wire

Rubber

Paper

Textiles

Ceramic

Wood