The mid-range continuous inkjet printer for all standard marking and coding applications

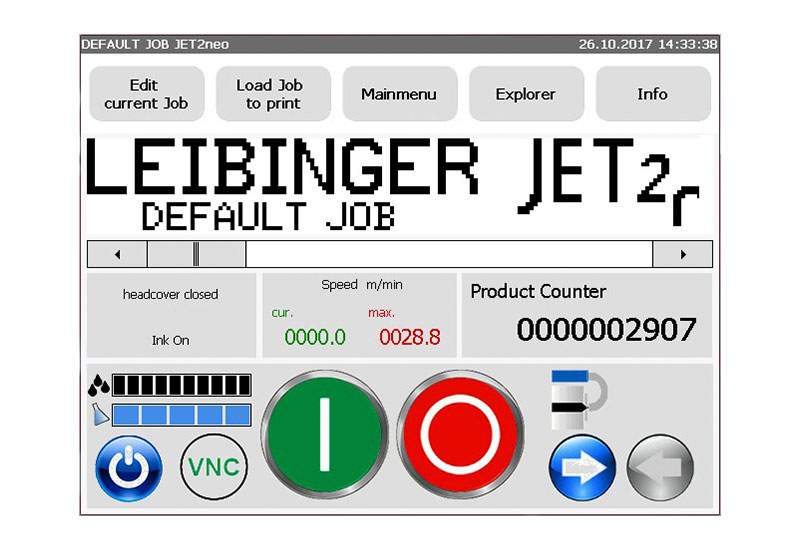

For customers around the world, the JET2neo is the “go-to” continuous inkjet printer, capable of all standard applications. Incorporating LEIBINGER’s unique Sealtronic technology, which minimizes downtime and maximizes productivity, the JET2neo is also known for its outstanding, German-made reliability.

The JET2neo prints data such as best-before-dates, production dates and lot numbers on up to three lines, with a variety of options and inks available – bringing you fast, reliable performance combined with low power and solvent consumption.

JET2neo at a glance

- Powerful CIJ solution for all standard coding and marking applications

- 3-line printing of fixed and variable data

- Up to 268 m/min

- Sealtronic print head technology rids clogging and frequent head cleaning

- High efficiency to help control operating costs

- Reduced solvent consumption

- Range of functions and interfaces

- Multiple inks available

- Ideal for most industries

Print on:

Glass

Carton

Film

Foils

Plastics

Metal

Wire

Rubber

Paper

Textiles

Ceramic

Wood