No cleaning required

Always ready to print with automatic

airtight nozzle sealing technology

Automatic airtight nozzle sealing technology - our secret weapon against downtime

The problem with continuous inkjet printing is that the ink has to dry fast. So any pause in production often results in dried ink and blocked nozzles.

Not with LEIBINGER’s unique nozzle sealing technology. When production stops, the nozzle retracts, closing the ink loop and preventing it from drying out. To start again, the nozzle extends out again and carries on printing – without the need for cleaning or rinsing cycles. After all, why clean something that doesn’t get dirty?

Since there is no cleaning cycle necessary, you don’t need additional cleaning solvent – which is good for the environment, the planet and your wallet. There is no impact on the viscosity of the ink or the quality of the first few prints either. Instantly reliable print quality without spitting or splashing.

In short, LEIBINGER unique technology removes the cleaning problem altogether so you enjoy faster start-up, greater productivity, lower costs and more consistent print quality.

With LEIBINGER printers your production line is ready when you are.

Stop cleaning

start coding

Automatic nozzle sealing technology

(also called Sealtronic) explained

Conserving consumables –

designed to reduce cost

We want our customers to produce a lot. And consume as little as possible. We minimize the amount of solvent and ink used through innovations such as the thermal barrier within the cabinet, which separates the ink circuit from electronic components. Keeping ink cool means less evaporation. And of course, Sealtronic technology reduces solvent evaporation by not exposing ink to the air.

In addition, our high-capacity ink bottles provide 19% more production in each bottle. Some cartridges require changing even though significant amounts of ink remain. Our bottles empty completely, giving you more print per bottle and an easy recycling with no hazardous residue.

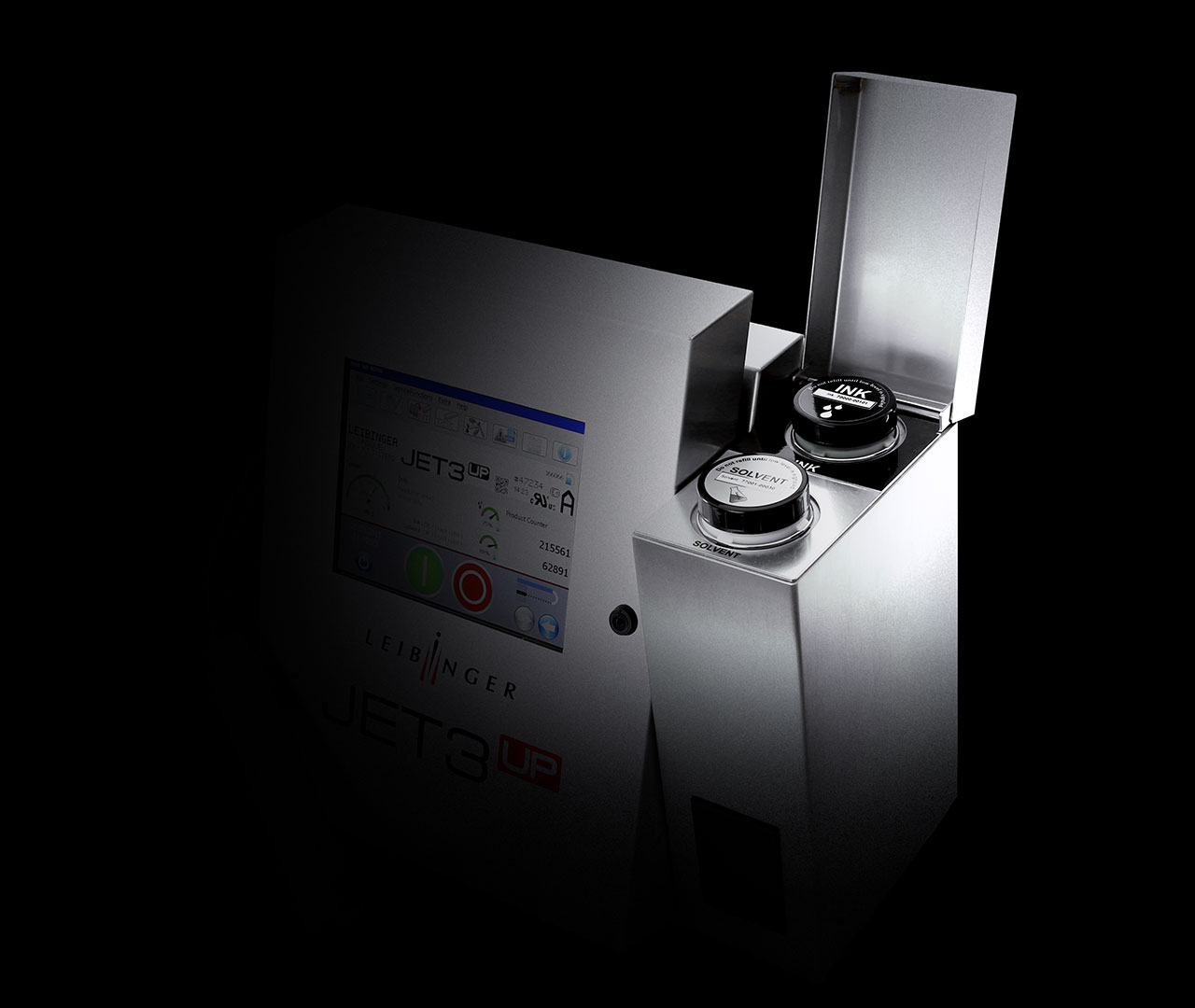

Made to last – and easy to maintain

LEIBINGER printers are not only made to highest engineering standards. They also have unique features that make them more reliable to use and easier for you to maintain.

The print head is made of highly durable materials – but is also designed so virtually all head components can be replaced separately if required. No need to replace the whole head.

The stainless steel housing is built to last, with minimal use of plastic, and our smart pump system runs every six seconds instead of running continuously. This means less wear and tear, lower power cost, a longer life – and it is also less likely to time out and cause unscheduled downtime.

LEIBINGER printers are designed for wasteless maintenance: simple enough to maintain in-house if you prefer, but we also offer our Maintenance PRO, low-cost preventative maintenance program if you would rather we did it for you.

Either way, each LEIBINGER printer will work hard and keep you productive for years.

Easy to use,

easy to integrate

Our products are designed to keep your production line moving. But we also know that they need to be easy to use and integrate: after all, time spent setting up the production line is time when nothing gets produced.

By providing a variety of different models along with a range of accessories, we ensure that LEIBINGER printers can be integrated into virtually any production line. We have pressurized print heads for dusty or wet environments. We have sliding tables, brackets, stands and the JETmotion traverse system to fit in with the way you work. You can adapt the nozzle size for finer printing, or the angle of the print head to fit in tight spaces. You can connect to every imaginable infrastructure or system through a range of connectivity options.

On top of that, we make sure it is as easy to use as your PC, with a clear and intuitive WYSIWYG display.

We wanted to make sure our printers fit effortlessly into your business – because we wanted you to spend less time setting up, and more time coding.