Industrial marking accessories

You can do so much more with original LEIBINGER accessories, inks and consumables. LEIBINGER printers can be combined with a number of accessories that can improve marking performance and simplify integration of industrial marking equipment into your production line. With our wide range of inks and other consumables, we handle all materials and production requirements.

Consumables

The right ink and solvent for the right task

We provide a complete range of inks and solvents for every inkjet printer, from fast-drying solvent inks to pigmented inks for legible marking on dark surfaces. We also offer specialty inks for complex customer requirements, such as color changing, sterilization, fluorescent, adhesive, alcohol-resistant and security inks. A member of the nanoInk Network, enabling us to collaborate with other industry players to improve ink formulation, we offer inks that permit outstanding print and resolution quality and offer extremely high smear and abrasion resistance. Colors include black, yellow, red, orange, white, blue, green, and silver-gray.

Software

LEIBINGER printers are already easy to use and rich in features: all JET3up printers include over 800 user-friendly functions as standard. But to make operation easier, and to make your production line even more efficient, there are a number of powerful software packages available.

V-check Vision System

An industrial marking accessory to keep an eye on quality

Production lines move too quickly for the human eye to spot mistakes. But the V-check Vision system can reliably detect incorrectly or incompletely marked products at high speed, ensuring that you can keep a constant eye on quality and avoid downtime. The V-check Vision system consists of a high-performance image sensor that can be easily attached to JET2neo or JET3up marking machines, and a removable 3.5" touchscreen display. Through early detection of faults, it ensures you avoid wastage and can continue marking at high speed and high quality.

JETmotion

The flexible way to print

Most industrial inkjet printing takes place one item at a time as it passes in front of the print head. The JETmotion traverse system, however, gives marking systems a mobile print head that moves across the items to be printed, for example packages, tubes, PCBs, electrical and electronic components, steel or plastic products. Easily attached to a JET3up or JET2neo printer, the JETmotion system uses a multi-axis system. It can also be optimized by the WINJET3 XY axis software, making it a perfect solution for intermittent motion production lines where text, such as date codes, can be printed onto multiple products side by side. JETmotion is yet another example of how LEIBINGER marking systems bring higher productivity to all production environments.

EcoSolv

Save money and protect the environment

Keep production costs down by minimizing solvent consumption with LEIBINGER’s unique EcoSolv solvent recycling system. A feature that is quickly and easily added to JET3up or JET2neo marking machines, EcoSolv recovers the evaporated solvent from the printer exhaust air through condensation and directs it back into the supply tank – especially useful in high-temperature situations. So you can help protect the environment while reducing solvent costs by 50%!

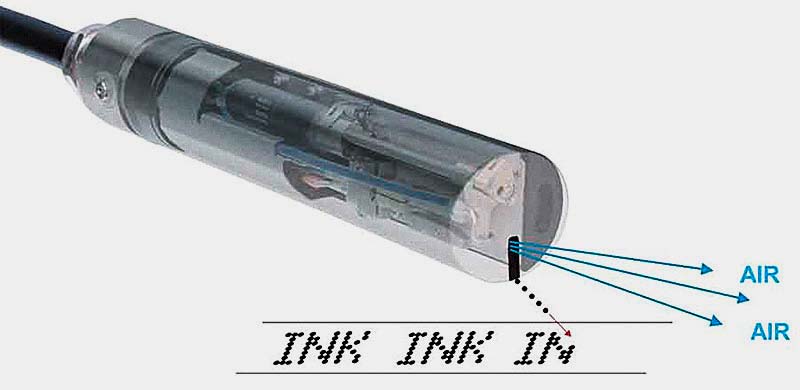

Head pressurization

Solving the dust problem

Dusty or humid production environments or overhead applications can be a problem for inkjet printers. Head pressurization technology, however, enables LEIBINGER printers to continue marking products unaffected. Because positive pressure is created in the print head, dust, dirt and moisture are driven away from the print area – enabling perfect marking and maximum productivity. For the internal head pressurization an integral compressor pump is typically used on JET2neo and JET3up marking machines, although the JET3up can be fitted with an external compressed air source for more extreme environments.

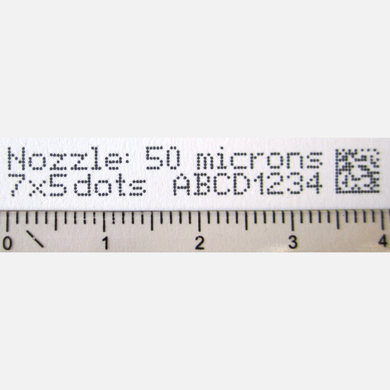

Adaptable nozzle sizes

For small character inkjet printing

LEIBINGER printing solutions can be adapted to use different nozzle sizes, which can help improve the quality of fine markings and reduce consumable costs. Nozzle sizes include 35 μm, 40 μm, 50 μm, 60 μm and 70 μm. A larger nozzle size is recommended for tasks such as large print or if the surface of the products is extremely absorbent or roughly structured, while a smaller nozzle size is used for micro-printing on smaller products. We would be happy to advise you and provide a free sample of print on your chosen material.

Installation accessories

Making integration easy

By providing you with a range of useful accessory products, we make it easy for you to integrate LEIBINGER small character inkjet printers into any production line. Accessories include sliding tables with print head brackets, cable guides with a print head bracket, printer stands, status lamps and cleaning stations. One particularly innovative accessory is the quick-snap print head bracket, which allows the print head to be removed and snapped straight back into perfect position to begin production again immediately.