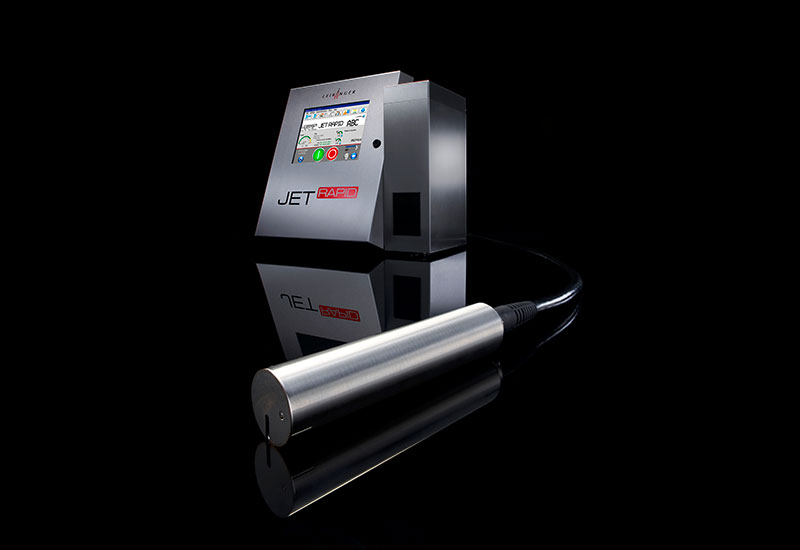

Sealtronic

LEIBINGER's world-famous automatic nozzle sealing technology

LEIBINGER's renowned automatic nozzle sealing technology, Sealtronic, ensures consistently high-quality printing without the need for cleaning procedures and ensures maximum printer availability. When the printer is not in use, the nozzle seals the ink circuit 100% airtight. This prevents ink from drying and lines from clogging, enabling instant start-ups and high-quality printing at any time. No clogging, no cleaning, simply smooth printing.