While our printers are only a small part of your overall production line, they play an essential role. Our machines print the codes, the serial numbers, the expiry dates on your products, so that they can be scanned, tracked, recognised and trusted by consumers and partners. When we talk about sustainability, the same principle applies. At first glance, compared to the rest of your production activities, the printer may make a small difference to your total environmental impact.

But these days, a small difference can mean a lot.

You need to think about sustainability in every aspect of your business. Your customers insist on it. Governments are enforcing it. Investors are attracted by it. If you can show that you are printing in the most sustainable way possible, it will not only ease your conscience. It will strengthen your business, satisfy the regulators and, ultimately, save you money.

Here are seven ways in which you can prove that you are doing your bit to make your printing as sustainable as possible:

1. Use less ink and solvent

Ink and solvent not only cost money – producing them also means using up natural resources. So we should do everything we can to minimise the amount we use – and the amount we pay for them. One important factor here is solvent recovery. Our new printer IQJET with its unique Eco-Mode feature, automatically seals the ink circuit airtight when not in use. This stops any solvent consumption. It also condenses evaporated solvent and feeds it back into the system. This results in up to 50% less consumption and emissions.

No wasted solvent, no emissions in the air and savings for you.

Does this make a big difference? Over the course of a year, we think so. Our printers consume only 2,7 ml per hour. Competitors without solvent recovery systems consume between 6 and 10 ml per hour. If you extrapolate that to a 3-shift operation with an average of 6,000 total hours per year, we can save you up to 43,800 ml of solvent per year, that otherwise would have evaporated into the environment. That’s quite a difference.

2. Go for the greenest ink

While you should choose products and consumables that comply with the latest safety and environmental regulations, such as REACH or RoHS, you can go further. Our inks are all REACH- and RoHs-compliant, but if you want to go MEK-free (ie using no Methyl Ethyl Ketone), we can also offer low VOC (volatile organic compounds) inks for further reduction of environmental impact.

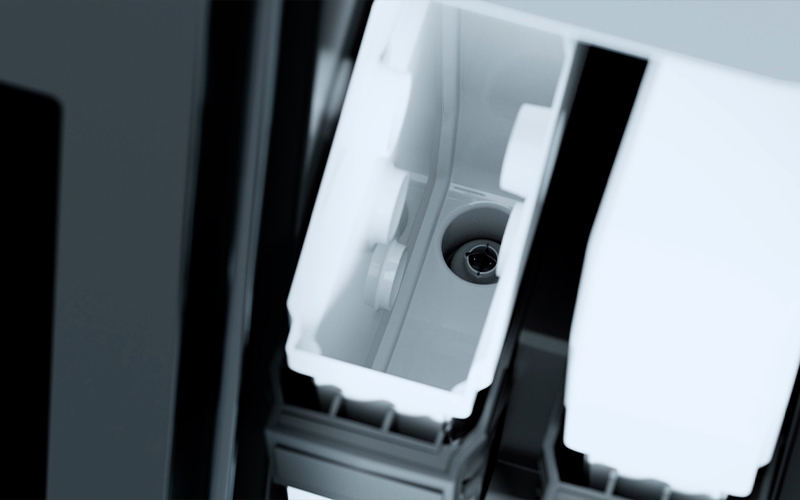

3. Get 100% out of every cartridge

If you have ever squeezed the very last toothpaste out of a tube, you will appreciate the importance of getting the most out of every print cartridge. Sadly, however, many printing systems demand a new cartridge even though up to 10% of the ink remains. LEIBINGER has designed its cartridges to use every last drop; when we say empty, we mean empty. The result is not only less wasted solvent and ink – you also use fewer cartridges over time, reducing the environmental impact of the materials used in the cartridge itself.

4. Recycle the cartridges

When your cartridge is finally completely empty (and not before) you will need to dispose of it and put a new one in. All empty cartridges should be 100% recyclable. Sadly, unlike IQJET cartridges, many competitors printer cartridges cannot be recycled due to the significant volume of waste remaining.

Another valuable point is hidden in the construction of the cartridges themselves – and how recyclable they are. LEIBINGER cartridges are made of just one kind of plastic (100 % PE) making them easier to recycle. The cartridges of many competitors consist of different components – the housing, the interior, the lid etc – which are often made from different types of plastic.

5. Choose printers with sustainable components

The same goes for materials used in the manufacture of the printers themselves. Where possible, look for machines with components made of stainless steel or other 100% recyclable materials, rather than plastic which is non-renewable and harder to recycle. The LEIBINGER IQJET has an entirely stainless steel housing and less than 10% of the components are plastic.

6. Go for quality that lasts

The most sustainable products are the ones that last a long time. Because we make all our printers ourselves, here in our factory in Tuttlingen, Germany, we can keep a careful eye on quality, with components that are designed to last. What’s more, if a part eventually needs replacing, we replace just that part – not the whole section (core or module). Just another small thing that helps to make a difference.

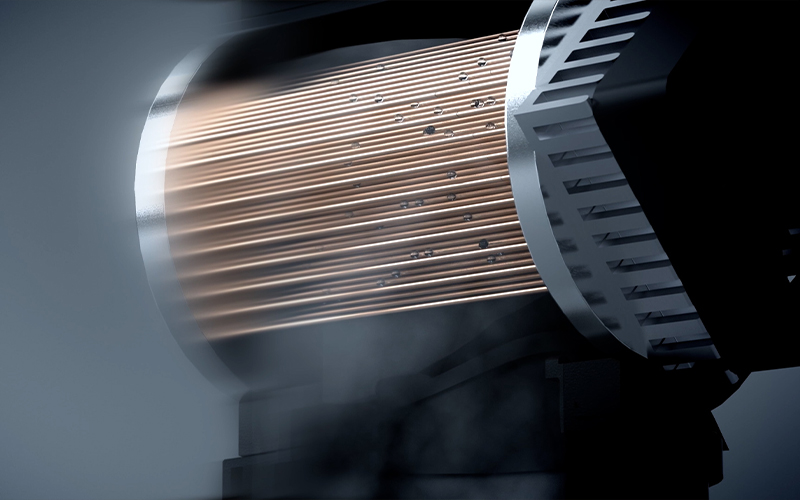

Higher quality products also require less maintenance, removing not just the carbon footprint of maintenance activities (all those white vans and service technicians driving around) but also the cost and inconvenience. In fact, the new LEIBINGER printer IQJET require no maintenance for five years, mainly down to a design that reduces wear and tear. For example, IQJET removes the need for a constantly running feed pump. We call it SMART.CARE, and it is another way to keep your printing function as sustainable as possible.

7. Minimize power consumption

Although an increasing amount of power comes from renewable sources, we all need to reduce the amount we use. Apart from anything else, it saves money. Choose where possible printers that deliver powerful print while drawing less power. With a rating of just 36W, the IQJET is the most frugal on the market.

Sweat the small stuff

The quest for sustainability and the need to combat climate change is perhaps the biggest single issue humanity has ever faced. That’s pretty big. But as a world of individuals, we also need to recognize that lots of small actions are necessary to create the massive change we need.

That’s why small things matter. It’s why your next car may be electric. It’s why you bother to recycle packaging. It’s why you turn down the central heating. And it’s why, as a production line manager, you choose to think carefully about your printing. Here at LEIBINGER, we’re delighted to be able to help you do it.

IQJET

The first intelligent coding & marking system

Plug & Print, 5 years maintenance-free and the best TCO values on the market thanks to low consumption of resources - that's what the LEIBINGER IQJET offers. This intelligent printer ensures undisturbed, carefree work and maximum productivity in your production, because the IQJET simply does what it is supposed to: Printing, printing, printing...