Bottle Coder - Coding and marking solutions for beverages

In the high-volume world of beverage production, pressure is high and margins are slim. Each conveyor belt carries thousands of bottles and cans every hour, and a date code needs to be printed on all of them. There are many different issues to consider: are you printing on PET, glass or aluminum? Why is CIJ the preferred technology? Can you print on primary packaging as well as on labels? Bottle coders will have to meet the demands of the beverage industry and and provide the reliability and speed that keep the conveyor lines going, no matter how big the challenge.

CIJ technology for bottle coding

Continuous inkjet printers (CIJ) are particularly well suited for the high speed, high volume coding and marking requirements of the beverage industry. Their sheer flexibility, which results in the possibilities for printing the various relevant bottle materials, i.e. glass, PET or metal bottles, characterize this technology just as much as the robustness, reliability and high printing speed of the bottle coders.

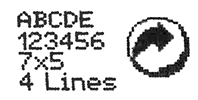

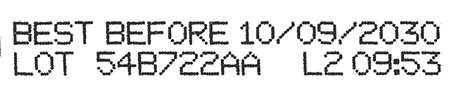

What kind of data is printed onto bottles and cans?

The main reason for coding and marking is to carry data about a product's freshness and for traceability in the supply chain. By printing dates on the container surface – or onto a label – this data is made available to retailers and customers. Codes can carry a range of information, such as a lot number which is of elementary importance in the event of a product recall. However, indicators of product freshness, such as minimum shelf life or expiration dates, are also usually required on bottles of all types. All the data can be applied cost-effectively and reliably by means of a bottle coder.

What surfaces and items do you need to print onto?

Various types of packaging are used for beverages, including metal cans, pouches, and plastic and glass bottles. You may also need to print onto labels or the outer packaging as well as the beverage container itself. LEIBINGER marking equipment has been designed to work effectively on any package surface.

Glass Bottle Coder

One of the main challenges facing a drinks business is green production or sustainability. Glass bottles, which are recyclable, are therefore often preferred. Washable inks are often needed since each date code must be erased and replaced when the bottle is recycled. All LEIBINGER inkjet printers can use washable inks.

Printing PET plastic bottles

Plastic bottles, mostly in the form of PET (polyethylene terephthalate) bottles, are very widely used, as they are light and unbreakable. There are returnable as well as non-returnable PET beverage bottles advances in the recycling and reuse of PET bottles are improving the eco-balance of this type of packaging, making it a alternative from this perspective as well.

Coding on aluminum bottles

Metal bottles made of aluminum are all the rage. This innovative packaging meets both high-quality design requirements and offers good protection for the contents. In addition, it is an advantage that aluminum is 100% recyclable. A date coder can be used to directly print codes onto aluminum, using the appropriate ink. Beverage coding on aluminum materials can be done at high speed with LEIBINGER equipment.

Beverage Carton Coding

Beverage cartons play an important role in our daily lives, providing a sustainable packaging solution that ensures safe access to essential fresh and nutritious foods. Print easily onto beverage carton packaging with continuous inkjet systems from LEIBINGER. The non-contact technology provides high quality printing and great reliability.

Printing on boxes

If you need to print a code onto a cardboard box that holds multiple bottles or containers, LEIBINGER printers can do it. Normally, this can be done with the same ink that is used for the primary packaging, as this also adheres to cardboard.

Bottle Cap Printing

Marking a date or code onto the small area of a bottle cap is one of the challenges for manufacturers. With our range of LEIBINGER small character solutions, codes may be applied to the caps of any type of bottle, even PET.

How are inkjet printers integrated into the production line?

For example, you may need your printer to be installed in a very small space, or at a non-standard angle. LEIBINGER offers a range of accessories, such as brackets and fixings, which make our coding and marking solutions flexible enough to fit in with the way you work. We also provide all the connections you need to ensure easy integration of each printer into your existing enterprise and production systems.

Key benefits of LEIBINGER bottle coders

Improve productivity and reduce downtime

A big challenge facing producers is the problem of clogged or soiled print heads. When ink dries on contact with air, the nozzle has to be cleaned before production can start again. LEIBINGER’s Sealtronic printhead technology solves the problem by creating an air-tight circuit. Most other coding machines expose the ink to the air, allowing it to dry and clog the nozzle.

Equipped with the automatic Sealtronic nozzle sealing system, LEIBINGER continuous inkjet printers remove the worry of production downtime. What's more, they use less consumables because no ink is wasted.

Keep going in difficult environments

Where is the weakness on your conveyor production line? If your printer is not durable enough, it may be the most likely reason for stopping production. However, LEIBINGER bottle coding systems are designed for extremes. If the air is dusty, we offer a stainless steel housing without plastic elements and a pressurized printhead - which ensures that dust particles are not able to interfere with printing.

Many beverage producers need to wash down marking equipment regularly to comply with stringent hygiene requirements. LEIBINGER beverage coding systems come with an optional IP65 protection in order to withstand the rigours of the daily wash-down.

Why use a LEIBINGER printer for bottle coding?

Whether you are printing onto PET bottles, aluminum cans, glass bottles or cardboard packaging, there is a LEIBINGER printer that will do the job for you perfectly. There are many reasons that a LEIBINGER printer is first choice for companies across the world.

Great versatility

LEIBINGER printers are easily integrated and can use any type of ink to deliver great results. Whatever codes and dates you need to apply, we have inks to make it a fast, high quality process.

Reliability and peace of mind

With Sealtronic technology, your ink won't dry out and your conveyor belt will not stop running. No clogged ink, no downtime.

Great service and support

The LEIBINGER name has been known as a sign of quality and service excellence in the beverage world for years. Any problems, you can contact one of our qualified experts, who will look after everything from maintenance and service to advising on how to optimize productivity.

LEIBINGER bottle coders

Keep your production running

IQJET - the first intelligent industrial coder to mark your bottles and packaging. Benefit from 5 years without maintenance. We keep you productive.