Looking for a continuous inkjet printer? 10 questions to ask first – and the answers you need

Adding a continuous inkjet printer to a production line is often an unavoidable investment because packaging and products need to be marked/coded with a best-before date or a LOT number. So you need to get it right. You need to search out the right kind of continuous inkjet printer. To help you, we've outlined some of the key points you need to consider and the questions you need to ask.

10 questions on CIJ printers

- What is continuous inkjet printing – and how do CIJ printers work?

- What effect do continuous inkjet printers have on productivity and efficiency?

- What surfaces can continuous inkjet printers be used on?

- What information do I need to print?

- How are continuous inkjet printers integrated into production lines?

- How fast do I need the CIJ printer to be?

- Is moisture a problem for inkjet printers?

- Is dust a problem for inkjet printers?

- How do I choose the right printer for my needs?

- Why should I choose LEIBINGER?

1. What is continuous inkjet printing – and how do CIJ printers work?

If you already know about non contact continuous inkjet CIJ technology, you can skip this bit. But if not, an understanding of the basics of coding and marking with inkjet printers is important.

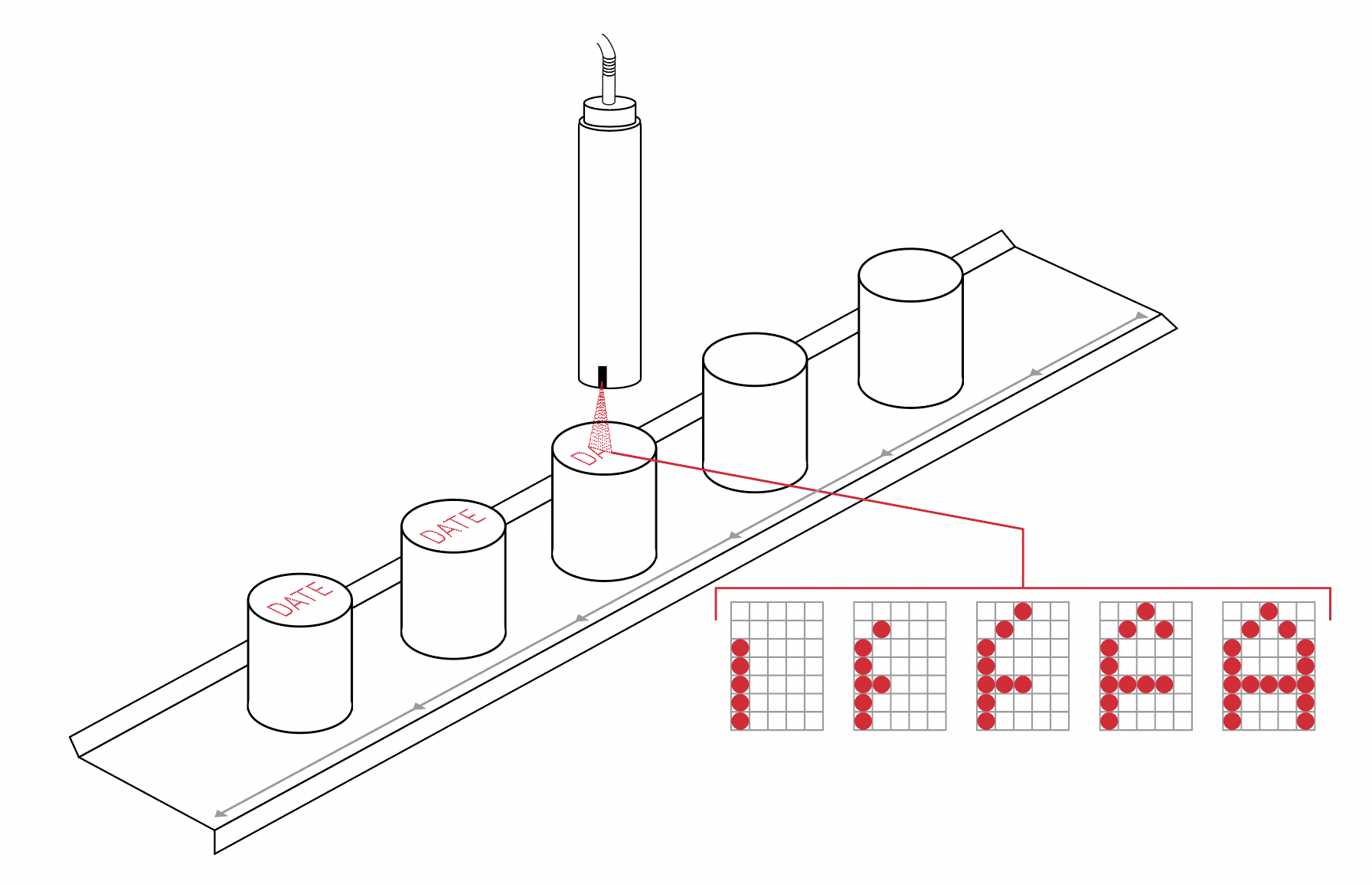

In short, continuous inkjet printers squirt a continuous 'jet' of tiny droplets of fast-drying ink. Some ink droplets are electrically charged and thus deflected by an electrostatic field onto a nearby surface to form characters, logos, bar codes or whatever you want to print. The other droplets – which are not electrically charged – return to the printer.

There are other non contact printing technologies, but each method has its drawbacks. Thermal inkjet TIJ systems, for example, use an ink cartridge that heats the ink. It then expels it drop by drop onto the print surface.

However, this non contact technology requires cartridges to be very close to the surface being printed. A CIJ printer printhead, by contrast, can 'throw' ink droplets at high speeds at a surface centimeters away. This makes continuous inkjet printing an ideal method for operation in a busy, fast-moving production lines where non contact printing is required.

2. What effect do continuous inkjet printers have on productivity and efficiency?

This is a key question – because downtime is to be avoided at all costs. One of the problems faced by manufacturers is that any pause in production results in clogging of the print nozzle on CIJ printers. Such pauses occur typically at the end of the working day or working week or on company holidays.

These pauses are a problem because the droplets of fast-drying, solvent based inks used in continuous inkjet CIJ quickly congeal. The result is that the print head has to be cleaned before production can restart, which takes time – and operation time is money. As companies search for solutions to this problem, they realize it is all about the industrial marking technologies used.

LEIBINGER's innovative Sealtronic technology solves the problem by automatically resealing the printhead and preventing exposure of the ink to the air when not in use. The unused ink droplets simply return into the printer.

The result is that no ink dries in the printhead. That dried ink will not affect coding or printing performance. No ink clogging, no downtime, no problem.

3. What surfaces can continuous inkjet printers be used on?

CIJ printers are used for all kinds of products and all kinds of coding applications, from food packaging to circuit boards. They can therefore be used to print codes onto virtually any kind of substrate from packaging carton to metal.

The choice of ink is key. Some marking inks do not adhere well to plastics or glass, for example, especially when you take into account the condensation that appears on chilled drinks. High-adhesion inks are therefore made available for manufacturers of drinks, frozen food etc.

What kind of ink is best for printing on cables? Which type of ink is preferred for marking absorbent materials or for high speeds? We can help with your choice of ink for marking the substrate of your choice. We make sure that jet of ink will adhere and produce a legible code or date on your product or packaging. We can even send you a sample!

LEIBINGER CIJ coder print fixed and variable text on any material

4. What information do I need to print?

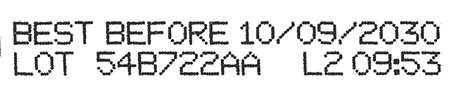

A continuous inkjet CIJ marking machine prints codes or other information on products or packaging. It is a key part of the solutions used to track and coordinate industrial production. By placing a code (or several codes) on any substrate, the machine effectively marks it for later identification. By marking a code, a continuous inkjet CIJ printer makes an item recognizable to tracking solutions or POS solutions. CIJ printers thus provide an essential service to producers.

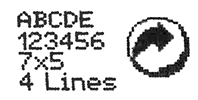

The information most commonly printed via continuous inkjet CIJ includes codes (2D codes, QR codes etc.), logos, expiry dates and batch numbers. They can be printed in all sizes and all colors, and LEIBINGER has created specialist pigmented inks that provide excellent high contrast and high resolution against dark surfaces.

Also, different products have different legibility requirements, requiring both large character and small character printing options. Codes, text characters and logos need to be legible and this depends largely on the size of the item being printed.

If you are printing on large items, a standard continuous inkjet CIJ printer will be fine. However, if you are printing a date or a code onto smaller items, such as electronic components, you may need a small character inkjet printer with a finer nozzle instead of a larger nozzle. An inkjet printer with a 35µm nozzle, for example, enables high resolution ink jet coding at a very small font size.

5. How are continuous inkjet printers integrated into production lines?

LEIBINGER CIJ printers are designed to fit easily into most industrial production line environments, and there is a range of accessories available to help this. CIJ printers must print as part of the overall process, dovetailing with other parts of the line.

These include software packages, that enable remote control of multiple industrial printers or a menu based WYSIWYG system for creating jobs, and brackets and fixings that enable CIJ printers to work at different angles to the production line. CIJ printers are often positioned in the smallest of spaces, so flexibility is important.

6. How fast do I need the CIJ printer to be?

Production lines run at different speeds so if your industry coding applications require faster printing, make sure you choose high speed CIJ solutions that can keep up. Some continuous inkjet printing solutions, like the JET Rapid for example, can offer high speed single-line printing up to 800m a minute. The JET Rapid Wire for cable marking even prints at a line speed of 1,000 m/min.

7. Is moisture a problem for inkjet printers?

Many food producers need to adhere to stringent hygiene requirements, which frequently involves washing down equipment, including CIJ printers. It may therefore be necessary to look for CIJ printers with IP65 protection in order to withstand the daily wash-down. LEIBINGER produces a range of CIJ printers to withstand all conditions - see the JET3up PRO as an example.

8. Is dust a problem for inkjet printers?

Continuous inkjet solutions are very precise tools, but they also need to be tough. Some industrial environments, such as food productions, timber yards or flour mills, can be quite dusty, which can affect the performance of continuous inkjet coding machines. These conditions require a sealed stainless steel housing and often a pressurized printhead. This ensures that dust particles are not able to interfere with printing.

9. How do I choose the right printer for my needs?

This is the big question, and we hope that some of the answers above will help you search out the right inkjet printer for your company and your industry. One advantage of LEIBINGER is that we can support you with advanced technologies, sophisticated features and a comprehensive service and maintenance program. Above all, we support you with a large range of high quality CIJ printer solutions.

Whatever print speed or operation you require, whether you want to print on metal, packaging materials or any other substrate, we have high quality inkjet marking and coding systems that are among the best solutions in the industry.

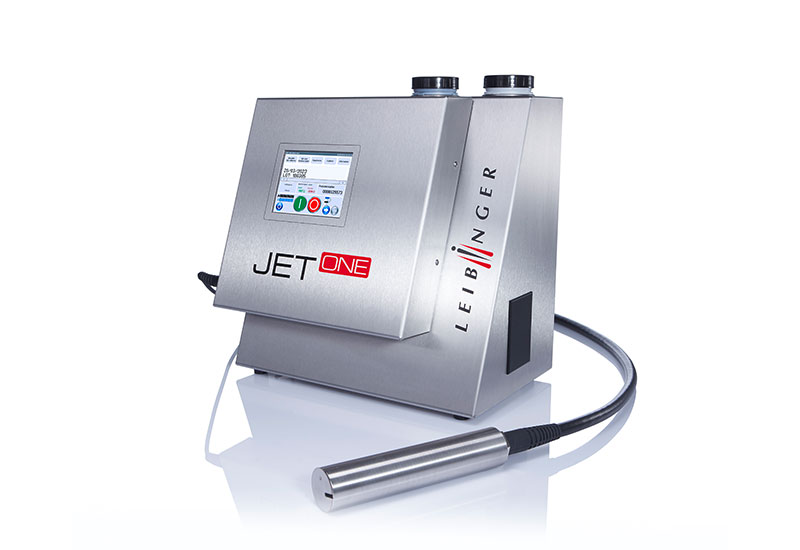

You can choose from the vary latest and fastest machines that feature specific technologies, or you can opt for a more affordable basic machine. Our JET One, for example, is an attractively-priced, entry-level model. It comes with Sealtronic technology and offers two-line printing that will support many industrial applications.

However, some industrial manufacturers would benefit more from the speed, performance and sophistication of the JET3up continuous inkjet printers, which we describe as the ultimate CIJ solution. It's the most feature-rich of our machines and will excel in the most complex and challenging coding and marking applications.

To get an idea of the range of CIJ printers available, why have a search around our main CIJ printer page where the specific characteristics of each machine are clearly described.

About LEIBINGER

Family-owned and operated since 1948, Paul Leibinger develops and manufactures continuous inkjet printers that code and mark products and packaging in all industries, in all parts of the world. The reason for our success is the innovative design that helps maximize uptime and improve production line efficiency. In addition, we are renowned for our global support and service, and our attention to quality, since every component is manufactured and checked at our own facility in Tuttlingen, Germany.

Get to know us

10. Why should I choose LEIBINGER?

The main reason is that we really believe that our continuous inkjet machines offer the maximum performance and the best reliability.

From the ease of integration and wide range of options and features to the unique Sealtronic technology, we have aimed to build the best quality continuous inkjet printers and provide them – along with our legendary maintenance, service and support – to companies all around the world.

We've aimed to make our CIJ printers reliable, cost-effective and hard-working because we know that those are the qualities you are looking for too. And we've been doing this since 1948 for our numbering machines and since 1996 for our CIJ coders.

Get in touch if you would like to talk more about continuous inkjet printers and how the benefits that a LEIBINGER CIJ printer can bring to your company. We would be delighted to hear from you.

Continuous inkjet printer from LEIBINGER

The intelligent CIJ solution

The first intelligent coding and marking system for all industries: Choose LEIBINGER CIJ printers to code your products and packaging. For best-before dates, lot numbers and other variable data – regardless of the material or surface.