The perfect solution to industrial coding and marking requirements: LEIBINGER industrial coders give you everything you need to be productive, driving down costs and improving quality. This is because we have spent many years perfecting our range of inkjet coders. For all industries, there is a LEIBINGER industrial coding system that meets your needs.

What is an industrial coding system?

What is industrial coding? Industrial coding equipment is used for marking text or symbols onto packaging or directly onto products (rather than using labels). The information printed is essential to the distribution, sale and use of those products.

What information can be printed?

LEIBINGER produces a range of high-quality, reliable inkjet printers that are used as marking systems in many industries. We aim to make them low-maintenance and to reduce the total cost of ownership, while keeping your production lines running uninterrupted and efficiently. The information printed includes the following:

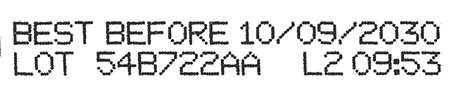

Expiration dates

Food products and beverages often need to have expiration dates to reassure customers of their freshness and safety.

Barcodes

Barcodes are often used because they can be machine-scanned. By marking with bar codes, product info and other variable data, products can be identified at all the different points of the supply chain.

Lot numbers

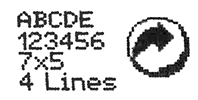

Lot numbers are often printed on the outside of packaging. Normally these prints have to be quite small and often covert. For example, limited space, e.g. on electronic components, also may require a very small print height.

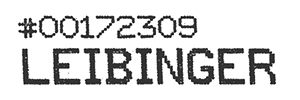

Logos

Complex graphics or logos can be printed using a coding machine, enabling a brand to be promoted.

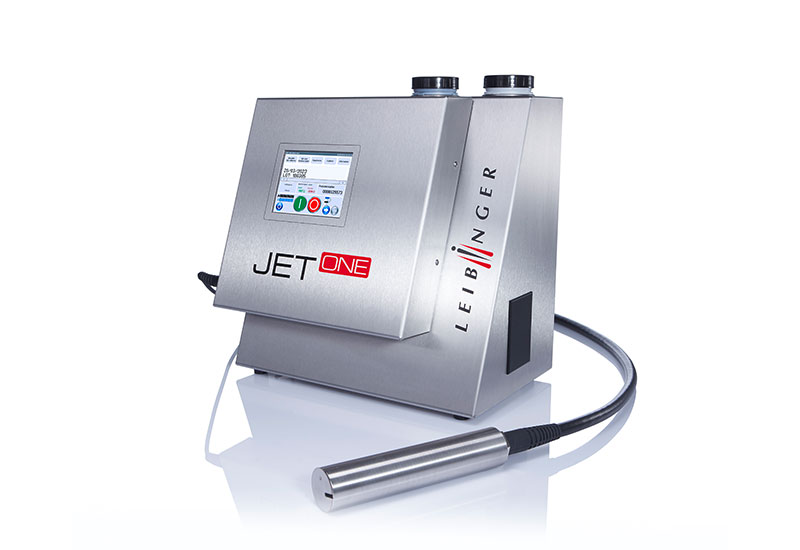

Industrial coders of LEIBINGER

LEIBINGER inkjet printing technology allows our inkjet coders to operate at high printing speed and with great clarity. Our continuous inkjet industrial coders are preferred to other technologies (such as valve drop-on-demand (DOD) printers, thermal transfer printers and laser printers) because of their flexibility and high printing speed. Continuous inkjet enables you to print clearly and reliably during the production run and can be used for marking almost any items.

Keeping your printing productive

Some inkjet coding printers delay the start-up of production while clogged print heads are cleaned. To avoid this, LEIBINGER Sealtronic® technology prevents the print head from clogging at all. When printing stops, the nozzle automatically seals itself from the air, and allows liquid ink to continue to circulate in the system. Nothing dries out, and the inkjet printer is ready to go again without interruption or downtime. This essential technology is only available in LEIBINGER printers.

Meeting a wide range of requirements

Our range of industrial inkjet coders meet the coding and marking needs of virtually all manufacturers. A wide range of inks and different models of coding systems, from Entry Line to High-speed Line allow an exact adaption to the needs of every requirement. In this way, the determination of the optimal and most cost-effective configuration also for your application is no issue. If you need high speed, an inkjet coder like the JET Rapid runs at a speed of up to 1000m every minute. If you need a small print height, choose a continuous inkjet model equipped with a 35µm nozzle size.

Protecting your coding systems from dust and water

If you need an IP65-protected, waterproof inkjet coder (to comply with strict hygiene rules of the beverage industry, for example), the JET3up PRO would be perfect. Some industrial environments, such as food productions, timber yards or flour mills, can also be quite dusty. This is why we also offer industrial inkjet printers with a sealed stainless steel housing and a pressurized print head. This ensures that dust particles are not able to interfere with printing.

Easy integration of industrial coding equipment

Our industrial inkjet printers are also designed to be easily integrated into your production lines. There is a range of accessories available to help this. These include software packages, that enable remote control of multiple machines or systems for creating coding jobs. We also supply brackets and fixings that enable inkjet coders to print at different angles to the production line.

LEIBINGER industrial coders print on all surfaces and materials

What types of materials/applications are suited to industrial coders?

Industrial coders are used for marking in many industries, including pharmaceutical, food and beverage, automotive and cosmetic. This is because they can print on any substrates including plastic, paper, wire, cables, resin, glass, metal, and even difficult porous substrates.

Different inks for different industries

LEIBINGER industrial inkjet coders are also designed to work with all kinds of inks. This is important because a high contrast ink may be needed on a dark background. Equally, a high-adhesion ink may be most suitable for date codes on wet glass or plastic bottles. They can print all kinds of information – whether graphics, logos, or expiration dates – in any colour ink and even at small print height.

Whatever your coding needs

Our marking systems can be used to print directly onto products or onto packaging, and can operate at the speed you need. Whether you need to print onto metal, paper, glass or any other material, we have coding systems that will suit you perfectly.

Why choose LEIBINGER industrial coders?

LEIBINGER has a reputation for quality that you would expect from a 100% German, family-owned business. Every day, all over the world, customers rely on our coding and marking machines for quality, reliability, speed and precision.

At our factory in Tuttlingen, we oversee the production of every machine and check it diligently before it goes out to a customer. We also manufacture virtually all components in the same factory. This means we can ensure that every inkjet printer will perform reliably for years.

We support you all the way

And you get the value of our support: a network of qualified experts around the world dedicated to keeping you and your systems running. We support our customers by offering advice on installation, and on how to choose the best system and ink for your needs. Together, our people and our world-renowned products, ensure that you can be as productive as possible and keep your total costs as low as possible.

LEIBINGER industrial coder

5 years without maintenance

IQJET - the first intelligent coding and marking system for all industries: maximum productivity and minimal operating costs. The ideal coding solution for your success.