What are inkjet coding systems used for?

Almost all products or packaging need to be coded in some form at some stage of production, whether to meet regulatory requirements for product safety, supply chain transparency, or to protect against counterfeiting. If you search for a flexible marking system that can print fixed or variable information such as Best-Before dates, bar codes or lot codes directly onto your product or product packaging, you should consider some key selection factors.

Advantages of inkjet coders

Simplicity

Any marking requirements can be implemented quickly and easily. Handling is carried out by existing personnel without the need for a lot of training.

Flexibility

They can cover all possible applications already as standard, regardless of the materials to be printed and in which form they are integrated into production lines.

Speed

They are suitable for marking directly during production in the fastest applications.

Cost effective

The lowest cost per print results from the direct printing on the packaging (without label), the yield of the ink tanks and the easy handling and maintenance.

LEIBINGER inkjet coders print on any material and surfaces

Types of inkjet coders

There are differences to consider, some of which are not obvious. There are two basic types of industrial inkjet coding machines, which use different principles to produce the printed text.

Drop-on-Demand

So-called drop-on-demand inkjet (DOD) printers produce a high-resolution printed image by generating multiple drops of ink individually by several small ink nozzles. DOD inkjets can be further differentiated by the technology used to generate the ink drops, with thermal systems being the most common. These systems are called Thermal Inkjet (TIJ) and are suitable for high-resolution applications and decorative prints with a lot of content.

Continuous Inkjet

Continuous inkjet printers (CIJ), on the other hand, create a continuous stream of ink drops, which are then shot from a single nozzle onto the product, where they are precisely placed at the intended location. The continuous inkjet printer, is best suited for printing codes, typically best-before dates, batch codes, bar codes and small logos, making it the system of choice for medium- to high-volume production when low cost per code are a priority. This is the case, for example, in the food and beverage, or the consumer goods industry.

Why it is important to choose the right inkjet coder:

The performance of coding and marking equipment inevitably affects the performance of your overall production and can become a drag on efficiency if the wrong system is chosen. There may be a risk of costly replacements after a short period of time or frequent production interruptions with high costs or even recalls due to faulty marking. So what factors should definitely be considered before purchasing an industrial ink jet system for production?

7 factors that should definitely be considered when purchasing industrial inkjet coders to avoid unnecessary costs

Factor 1: Print content and fineness

First of all, it must be clarified which print content (number of lines of text, alphanumeric characters, codes or graphics) is to be printed on the products or packaging. It is also important to know whether the print is decorative (e.g. colored areas or high-resolution logos) or informative human- or machine-readable in the form of product coding.

The latter codes are usually relatively small, up to 5-line codes. Examples are date code, best-before date, batch number, 2D codes, small logos, or a few lines of text or alphanumeric codes to convey important content to consumers or within the supply chain, for example.

Continuous inkjet printers can print up to 32 drops in height, which is up to 5 lines of text or corresponding 2D codes. So CIJ it is specifically designed for product coding and is best suited for those applications and needs.

If significantly more content or a decorative element and therefore superior print quality is required, another type of inkjet printer, such as the TIJ, may be considered.

Factor 2: Installation situation

Industrial inkjet printers are usually used directly in production lines and must therefore be designed precisely for this purpose. The inkjet coder should be able to be integrated into the system quickly and easily - plug & play, so to speak. It makes sense for the printing to take place during ongoing production. Space is often at a premium and installation options are limited. An inkjet coding system must be able to cope with these conditions as standard.

An inkjet coder is recommended in which the print head itself is very compact and can be guided on a cable - up to 10 m long - to the exact point in the production machine. Different print head variants should be available that allow the product to be printed from all sides (including overhead or from below). Interventions during ongoing production, such as cartridge changes at the head, should not have to be carried out for safety and productivity reasons.

Factor 3: Surface and material properties of the products to be printed

There are inkjet coders for virtually all conceivable substrates to be printed. Not only absorbent surfaces such as paper or cardboard can be printed, but also all types of plastic, glass, metal and natural products.

The surface shape of the product to be printed also plays an important role. There are inkjet printers that can handle irregular surfaces well, since a distance of the print head from the product of one centimeter or more is no problem. For example, convex, concave or other shapes can be printed with a continuous inkjet printer without any problems, as it can compensate for variations in distance to the product being printed. DOD-based printing systems, on the other hand, rely on getting close to the product being printed to produce a clean print.

CIJ printers offer a comprehensive range of inks for all materials and required properties in the production environment.

Factor 4: Required print speed

Or to put it another way, how many products do you want to mark per unit of time (e.g. hour). It is important that your line sets the pace and that the industrial inkjet coding machine can keep up with it. This is because industrial marking systems are generally used directly in ongoing production. Of course, they should not be the reason why the production line has to be slowed down.

As with office printers, however, higher print speeds for industrial inkjet coders come at the expense of print resolution. If you want to print particularly high-resolution and a lot of content, this usually comes at the expense of speed. However, in the area of coding with, for example, date codes, a somewhat lower resolution is acceptable and usually not very much print text is required. With the right inkjet printers, this allows very high speeds of up to 1000 meters per minute (equivalent to 60 km/h). Continuous inkjet are the appropriate systems for this type of marking.

Factor 5: With which industrial inkjet coding machines am I future-proof?

As a rule, you want a system that exactly meets your requirements both today and tomorrow. Of course, not all future requirements are known today. For example, the production volume could increase over time and therefore a production could be operated in multiple shifts or at higher speeds. The product mix could also change. Therefore, go for an inkjet coder that offers flexibility.

Factor 6: What about Total Cost of Ownership (TCO)

Successful production companies are cool calculators. Maintaining competitiveness means ongoing cost optimization. That's why a coding solution must pay close attention to running costs. These come in the form of maintenance, consumables, energy consumption and spare parts prices. There are cases where, within just a few months, an extremely low initial investment is offset by a very efficient inkjet coding system that is, however, somewhat more expensive to purchase. Therefore, ask specifically about maintenance frequency and costs for replacement components (e.g. maintenance kits). When comparing different inkjet coders, always include consumables costs and consumption in the TCO calculation. But also never ignore the hidden costs that can result from having unreliable equipment in your high-performance manufacturing facility.

Factor 7: Avoiding downtime

What you don't want in a highly efficient and productive operation is an inkjet coder that constantly breaks down, has to be cleaned again and again, or doesn't start up when you want to start the production run. If that's the case, you'll quickly lose so much money in production downtime that you could just as easily buy a whole new set of premium coding equipment - or much more.

Therefore, pay attention to the highest reliability of the marking systems, a clean integration into your production line and safe operability by your personnel. These are the key factors for unrestricted production uptime.

Why choose LEIBINGER Inkjet Coder?

LEIBINGER Inkjet Coders are based on the flexible, cost-efficient Continuous Inkjet technology, but offer decisive reliability and cost advantages compared to conventional systems of this kind.

Sealtronic® printhead technology

This technology integrated in every LEIBINGER printer makes LEIBINGER's industrial marking systems resistant to contamination and prevents the ink nozzles from drying out. This accounts for the decisive productivity and cost advantage. Time-consuming cleaning work before, after or during production runs can be effectively avoided, saving you valuable time - in the form of production time and the working time of your production staff. This in turn means hard cash.

2 years maintenance free*

LEIBINGER offers the longest maintenance interval in the market. For regular maintenance only a few individual components are replaced, which is cost- and environmentally-friendly. Thus, LEIBINGER offers the most sustainable and transparent maintenance concept without any nasty surprises.

*standard applications, up to two shift operation

Highest quality

In general, LEIBINGER offers highly reliable inkjet coders "Made in Germany" which are manufactured according to the strictest quality standards to ensure that they remain reliable.

Ease of use

LEIBINGER printers are also characterized by their ease of operation and integration into your production systems. This means that your production staff can always be sure that exactly what is required is printed on the product.

Summary

This combination results in LEIBINGER being one of the most sought-after solutions for sustainable cost-efficient product coding for manufacturers and packaging lines all over the world. Our reliable, high-quality coding and marking solutions are designed to keep you productive. This has been our mission since 1948, the year LEIBINGER was founded as a company.

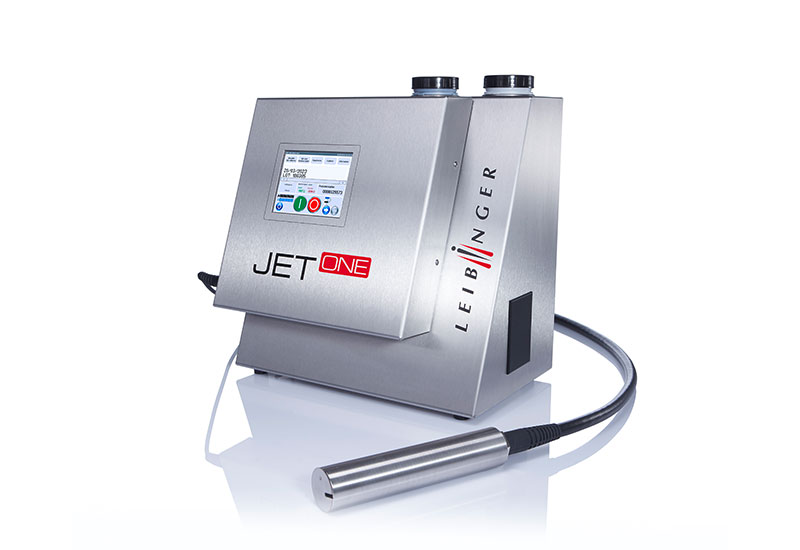

LEIBINGER inkjet coders

The intelligent coding solution

The first intelligent coding system for all industries: Choose LEIBINGER inkjet coders to mark your products and packaging. For example with best-before dates, lot numbers and other variable data – regardless of the material or surface.