Printers, food packaging and production excellence

If you are in the food packaging industry, you probably know all about food. But how much do you know about food packaging printers – and the essential role they play?

Why do we need marking or coding?

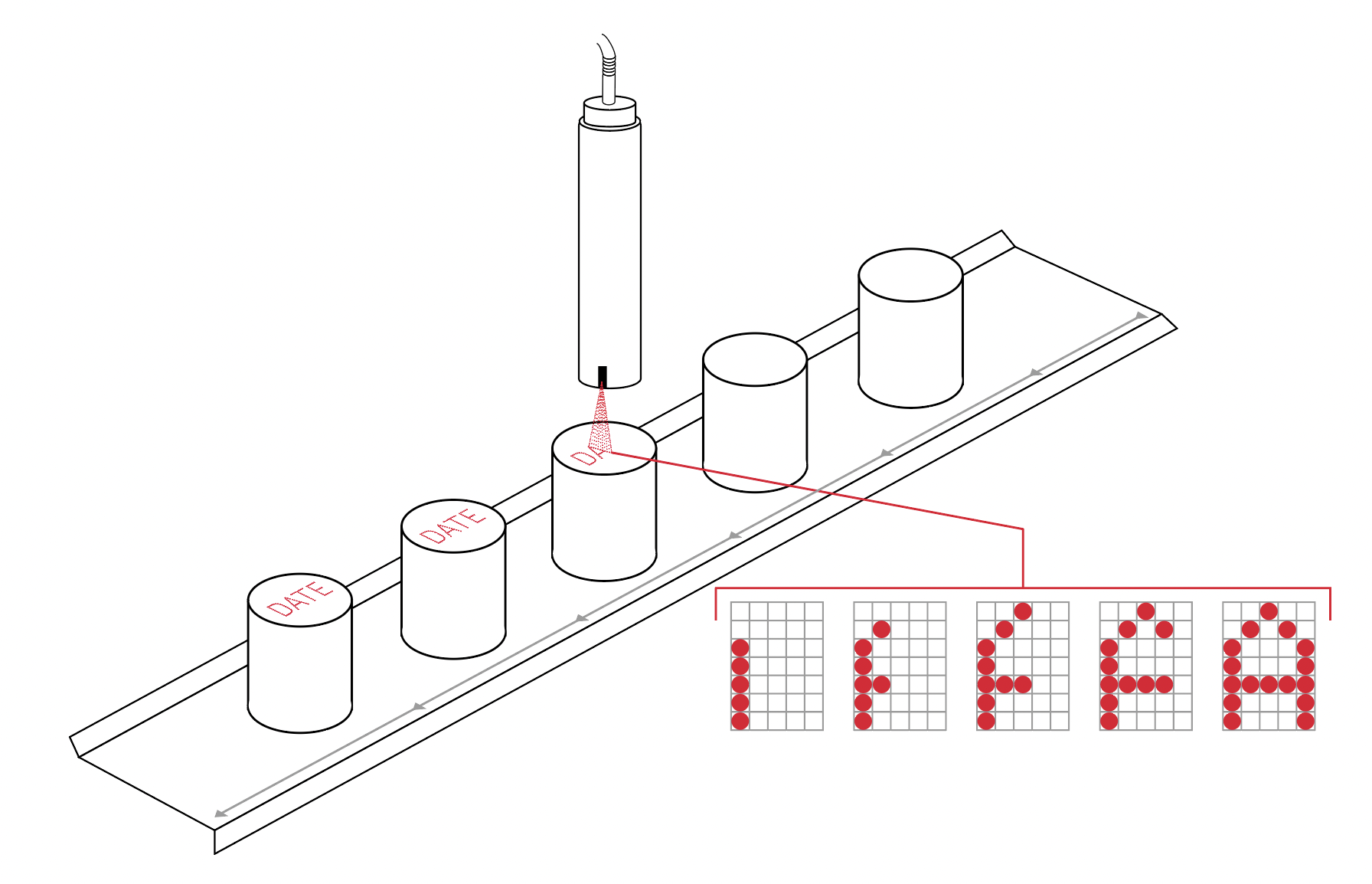

Everyday millions of edible items are produced, packaged and sold. Almost every single item has some kind of code printed on it.

In all parts of the world, there are various legal requirements that require the marking of those products and their packaging. This may mean printing on paperboard cartons, plastic wraps, metal cans, glass bottles, labels or even secondary packaging.

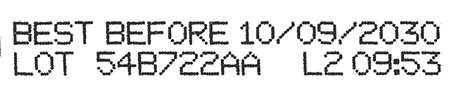

Packaged food needs to carry batch numbers or expiry dates, often in the form of barcodes. They inform consumers and retailers about the products, contributing towards traceability and food safety. Coding solutions are therefore a key part of every production line in this industry.

What printing and coding technologies are used?

In the market today, margins are tight, so food manufacturers need marking solutions that are efficient and economical, printing at high speed and low cost per item. For many companies the chosen printer technology is therefore continuous inkjet printing (CIJ). Thermal inkjet printers can also be used, but CIJ is more suitable for high volume printing that is typical in food production.

What packaging materials can I print onto?

Food packaging comes in many different formats using different materials, such as porous and non porous substrates. They come in different shapes too: whether it's a cylindrical container or a flexible pouch, you need accurate, reliable coding solutions that can handle any shape. LEIBINGER printers are able to cope with any of the following formats used by the food packaging business:

-

Bottles/jars (plastic or glass)

-

Cans (aluminum or steel)

-

Tetra Pak cartons (aseptic paperboard containers)

-

Pouches (often foil laminated)

-

Flexible packaging (films and laminates)

-

Boxes (cardboard or corrugated)

-

Trays

-

Tubes

-

Bags (of any material)

What sort of printing inks should I use?

LEIBINGER printers are designed to use a range of different inks, depending on your requirements. For example, UV inks may be used to combat counterfeiters and high-contrast ink may be preferred to give contrast against a dark background. In the food packaging business, printing with a high-adhesion ink is a very useful option, since it is more effective on cold, damp surfaces such as the exterior of chilled food products

Do printers need to be water resistant?

In the food industry, an enclosure protectiong against the ingress of water or dust is a big advantage. Owing to stringent hygiene and cleanliness requirements, the production environment must often be hosed down. Challenges like this are no problem for printers like the LEIBINGER JET3up PRO.

It is a printer that comes with a fully enclosed unit that conforms to IP65 standards and can withstand any washdown, making it the perfect solution for coding and marking in the food and beverage industry.

LEIBINGER: an established partner to the food packaging industry

Regardless of which coding machine you select, you can trust in LEIBINGER food packaging printers and the worldwide support team that comes with it. LEIBINGER is a family-operated enterprise with a brand known for quality: we lead the industry in terms of innovation, reliability and support.

Every LEIBINGER printer is produced at our Tuttlingen, Germany factory, ensuring quality control before shipment to the customer. Additionally, we have a group of LEIBINGER specialists in virtually every geography. There is always a nearby expert available to offer guidance, maintenance and repair services.

By printing codes onto your products, you help your customers by improving safety and traceability. By providing high quality coding solutions, we help our customers like you by giving you productivity, reliability and excellent value.

Food Packaging Printer

5 years without maintenance

IQJET makes printing on packaged food easy and efficient. From expiration dates to barcodes and company logos. Maximize your uptime with LEIBINGER's intelligent food packaging printer.