What do food manufacturers have in common with drugstore or pharma item producers? What do beverage fillings systems use that are also found in egg sorting machines? There is a technology that helps virtually every industry to run more smoothly: case coding.

What is case coding?

Case coding describes the use of inkjet printers to apply codes or marks onto packaging or labeling (or sometimes the products themselves). It is not a glamorous part of production, yet it is absolutely essential to the smooth operation of businesses of all kinds around the world.

Why are case coders necessary?

In short, case coding carries information. Product packaging is often colourfully cluttered with all kinds of messages, but case coders add messages of a different kind.

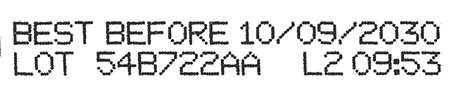

The codes are applied on the production line, and therefore contain information about the production – when and where production took place, the batch number, the expiry date, the quantity of product per case etc.

Codes can be in a number of different formats. Sometimes, plain text such as food date codes is printed onto product packaging (or onto labelling). Alternatively, codes can be machine-readable: barcodes and QR codes are designed to be read by scanners (or mobile phones). In addition to these ‘functional’ codes, the case coding process also allows logos and other symbols to be applied – which helps to remind customers of the brand behind the product.

Who benefits from case coding or case printing?

Case coding (also called case printing) makes information available to two different groups of people: customers and supply chain. As mentioned above, customer are more likely to buy a product if they feel well informed and confident of its high quality. So if a high resolution logo is applied, for example, to the outside of a box of wine bottles, it is a sign of reassurance aimed at those who recognise the brand.

However, case coding is more than just reassuring to the supply chain – it is essential. At each stage of the journey from factory to customer, products need to be transported and stored – and much of this process is automated. The only way that millions of brown cardboard boxes on pallets can be distinguished from each other is by scanning visible bar codes – applied by case coding technology when the products left the factory. The automated systems that run logistics operations are then able to reliably put the right amount of product in the right part of the warehouse or on the right truck in order to ultimately find its way to a delighted customer.

Without case coding, identification of products – and therefore their distribution and sale – would be manual, slow and error-prone.

What kind of case coding printer is required in each industry?

Case coding is typically enabled by continuous inkjet printers positioned along the production or packaging line. But not every industry will require the same case coding printer. Different industries will have experience of different packaging/production environments, and therefore require a different approach to coding.

One of the main ways in which case coding requirements may differ from one industry to another is in the substrates that the coding needs to be applied to. LEIBINGER works with customers that produce and package many different products. Cardboard, for example, is more absorbent than plastics. Inkjet printing manufacturers like LEIBINGER therefore provide a variety of different inks to deliver high resolution print each surface.

Some production lines run faster than others. In cabling industry applications, for example, continuous inkjet (CIJ) printers need to handle very high print speeds. The JET Rapid Wire is designed specifically for character printing on cables and pipes and can operate at 1,000m/min. LEIBINGER coding solutions also have an extra benefit – Sealtronic technology which prevents clogged nozzles and therefore avoids the downtime associated with printer cleaning.

Production environments vary too from industry to industry. Industrial inkjet printer equipment needs to cope with high and low temperatures, dust and moisture. This is why LEIBINGER offers specialist CIJ printers designed to excel in such situations.

Dairy >>>

Confectionery and snacks >>>

Cereals, flour and baked goods >>>

Convenience products >>>

Other packaged foods >>>

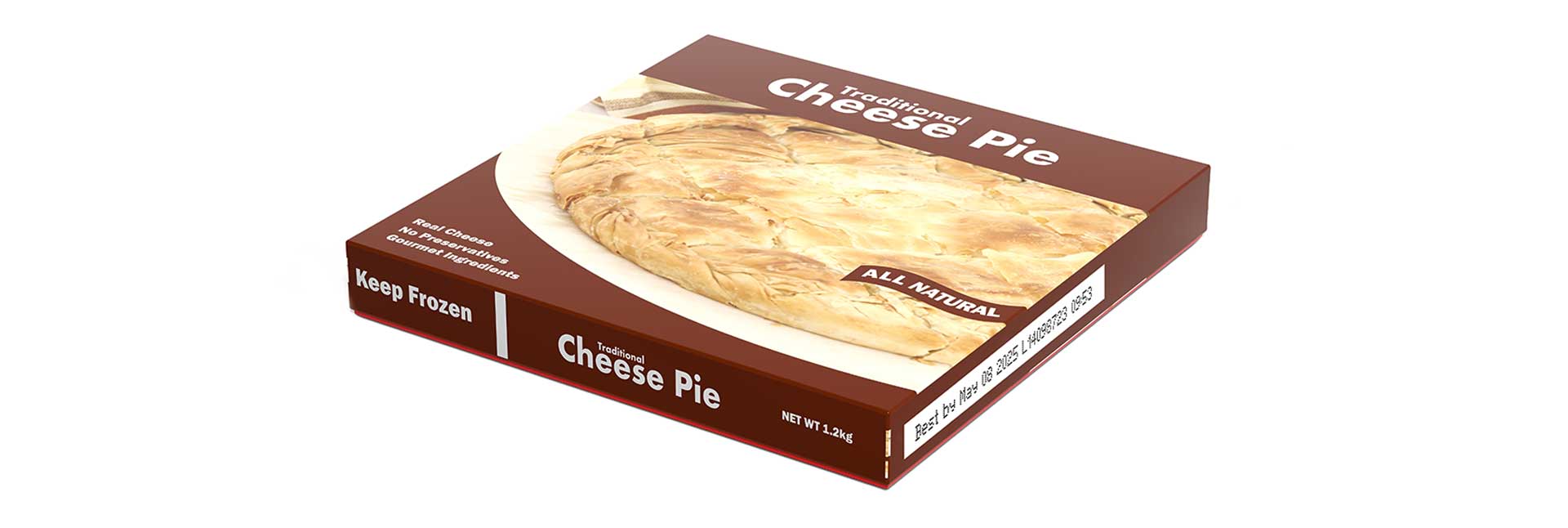

Frozen food >>>

What accessories are required for effective inkjet coding?

Inkjet coding is a small but important part of the production process - and it is important that it is efficiently integrated. LEIBINGER helps its customers to ensure this by providing not just a range of different printer solutions, but also a series of useful accessories to make the production line as efficient and productive as possible – whichever industry you work in.

JET One

It all starts here

Attractively-priced entry-level printer offering two-line printing on a variety of materials and featuring unique Sealtronic technology. more >

JET Rapid

The need for speed

Specialist high-speed printer offering speeds of 800m/min for a range of high-output applications. more >