Virtually every product we touch, every packet of food we purchase, every can of cold drink we lift to our lips carries product marking of some kind. These items are not generic - almost every one carries some kind of information that makes it unique. Product marking is ubiquitous – and essential to the way the modern world works, the way people buy and use products, and the way companies sell them.

But what are these marks and symbols? What do they say? Why are they so important? Let’s take a look at the often hidden information exchange that is happening in the world of product marking.

Product marking for consumers and for businesses

First of all, it’s important to note that product marking is there for two reasons. First, it is there to inform customers or users of the product itself. But second, product marks are also there to facilitate the commercial process itself.

These marks and symbols provide a unique identifier that manufacturers, resellers, logistics companies, and retail outlets use to quickly identify a product - and therefore to apply the right price, and maintain the right amount of inventory. Without product marking, this would be at best inefficient – at worst, impossible.

Specifications – give me the detail

At first sight all kinds of cable may look the same - at least to the untrained eye. But written neatly along the length of the wire at regular intervals, will be information confirming various important technical details: the resistance, the capacity, the gauge and so on.

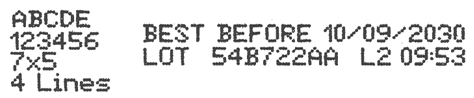

Using CIJ printers to apply a product mark enables manufacturers to produce lots of different types of product, for example in the cable industry. The extrusion process is used to create cables of different specifications, in a high-speed, high-volume process that creates many miles of cable every working day. However, CIJ printers, such as those made by LEIBINGER, are fast enough to print product information legibly onto every length of cable at speeds of up to a kilometre every minute.

And because it is easy to change the information printed, a cable manufacturer can switch cable types and the printers easily keep pace with production demands.

Best-before dates

Best-before, or expiry dates, are frequently printed on food products, via labels or by direct printing on the product packaging. Although not consistently mandated by law, supermarkets usually insist that food producers apply such marks.

Bar codes and QR codes: the digital shorthand you don’t need to understand

Frequently printed onto product packaging, labels or the products themselves, barcodes and QR codes can be easily scanned to identify the product, the batch, the provenance and lots of other information. While these codes are increasingly used by consumers – for example to direct them to informative websites or to online promotions – they are mainly used within the supply chain. At each stage, they are scanned in order to help logistics systems to manage the storage and distribution of products.

Logos are for loyalty

Product manufacturers invest a lot of money into their brand and reputation. It is often desirable, therefore, to remind consumers of that brand with a logo or symbol, printed directly onto the product. This is useful in the battle against counterfeit goods, with the pharmaceutical industry, for example, keen to prove the authenticity of a product.

Safety first with product marking

Manufacturers in the pharmaceutical industry also benefit from improving customer safety and meeting compliance requirements with product-marking on product packaging. A range of warnings or safety symbols can be clearly shown, and consumers can be clearly informed on the nature and expiry date of medicines. Providing expiry date markings on food packaging is also an important part of the food production process.

Take advantage of years of product marking experience

LEIBINGER helps companies in virtually all industries to design and operate product marking equipment. Since we are a family-owned company that has been specialising in continuous inkjet printing equipment for three generations, we bring expertise and understanding of the challenges facing industries of all kinds.

Meat, fish, seafood and poultry >>>

Confectionery and snacks >>>

Pharmaceuticals and supplements >>>

Wires, cables, tubes and pipes >>>

Everything you need for successful product marking

LEIBINGER not only provides a number of printers to meet your product marking requirements. We also offer a range of accessories, inks and software tools that help you to ensure the fast, accurate application of marks and symbols onto products of all kinds. If you need to mark or code your products, we can help.

JET Rapid

The need for speed

Specialist high-speed printer offering speeds of 800m/min for a range of high-output applications. more >

JET2neo

The productivity machine

The mid-range printer for all standard marking and coding applications, printing up to 1,777 characters/second. Prints up to three lines. more >