How can a CIJ printer help your business?

CIJ printers are used in factories around the world to mark codes or characters onto products or their packaging. But how do they work? What are the advantages? And are they right for your business?

What is CIJ printing?

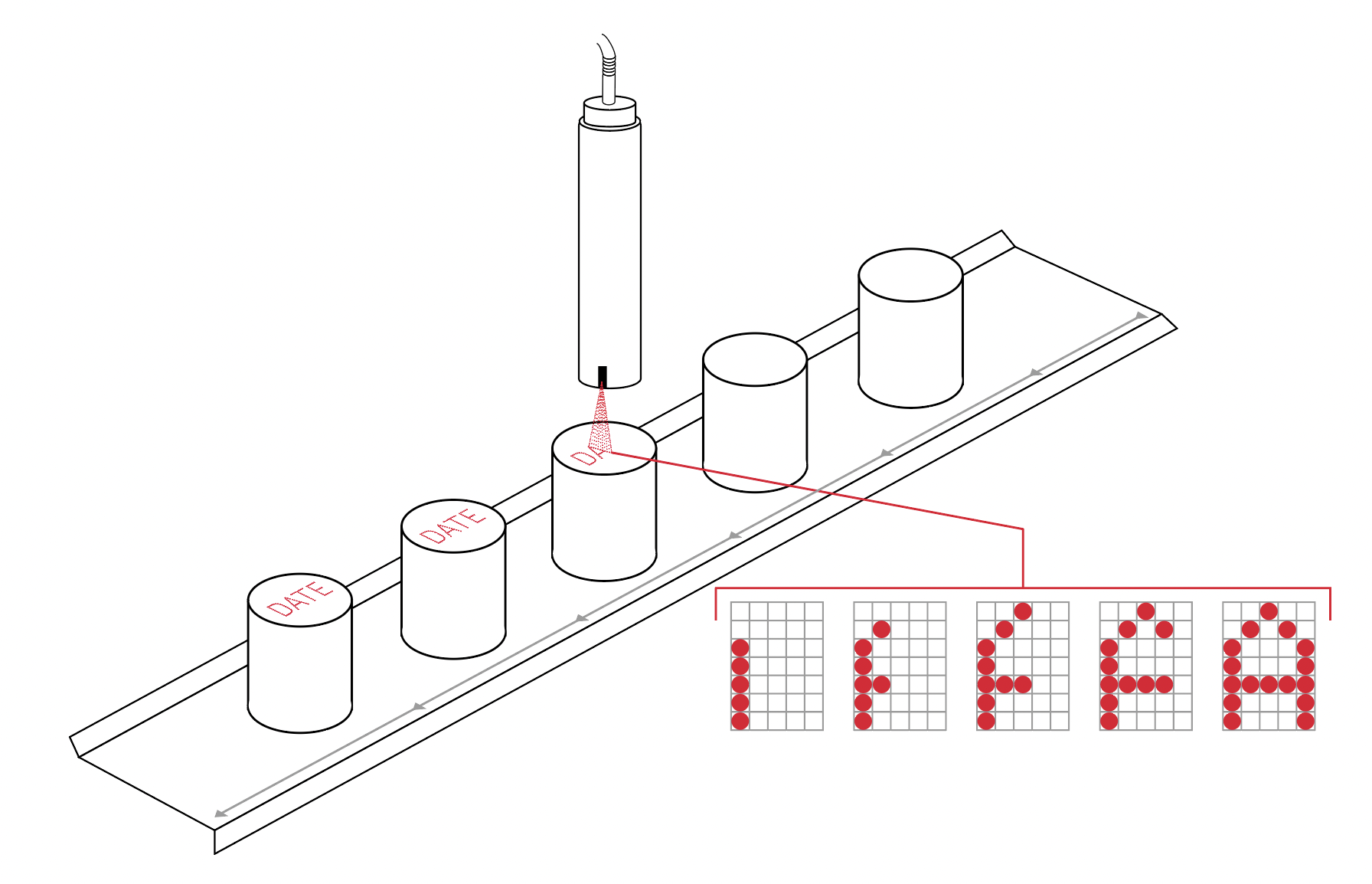

In printing CIJ means continuous inkjet. It gets its name from the fact that it involves a continuous stream of ink, that is constantly circulating through the print head.

How does a continuous inkjet printer work?

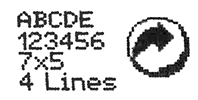

The tiny ink droplets in this stream are electrostatically charged and can therefore be diverted from the continuous stream as and when required. The droplets are precisely guided by deflector plates onto products as they pass within a few millimetres of the print head – forming the shape of letters, numbers or bar codes.

What are the alternatives to CIJ printing?

Laser printing is a technology sometimes used in manufacturing – but it involves the physical etching of characters into the substrate with a laser. The downside of laser printing is that it is less effective on porous surfaces and has a higher upfront cost. In addition, laser printers require expensive ventilation systems. As a non-contact printing method, CIJ is also often preferred to laser systems for delicate products such as PCBs (printed circuit boards).

Thermal inkjet printing (TIJ) is another alternative. TIJ printers use heat to expel ink onto a nearby surface. However, the surface has to be just a few millimetres from the printhead, increasing the chance of errors or smudges. A CIJ printhead, by contrast, can print on both flat and curved surfaces that are up to 30mm away. Continuous inkjet printers are also generally considered to be faster than TIJ, and capable of handling a wider range of surfaces and substrates, e.g. paper, metal, cardboard, plastic and glass.

Which industries can benefit from continuous inkjet printers?

Since product codes and barcodes are used to track all kinds of goods throughout the supply chain, most industries have a need for continuous inkjet printers. For example:

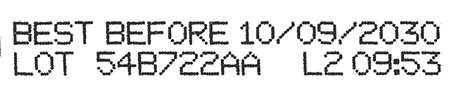

- Food producers print expiration dates on fresh and frozen food.

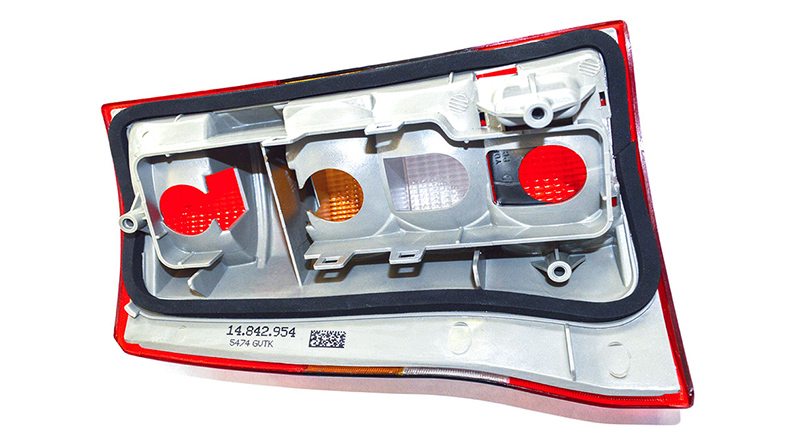

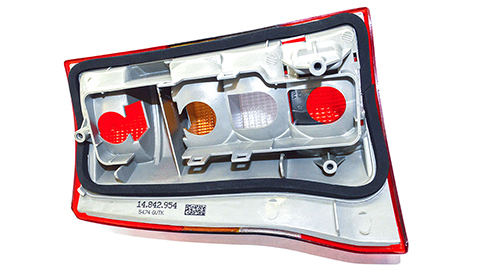

- The automotive and electronics industries apply serial numbers onto components, such as automotive parts and PCBs.

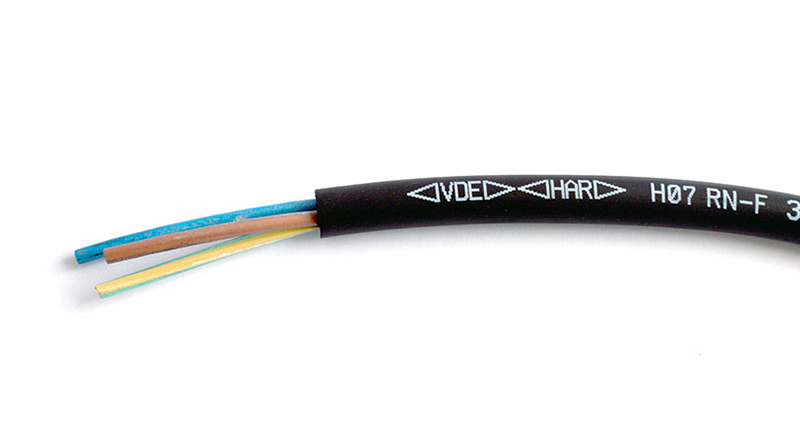

- Manufacturers of wires, cables, tubes and pipes use specific types of CIJ printer to print product information along the length of each product.

- Cosmetics, personal care and cleaning products also use CIJ printers to apply batch codes that help traceability.

- For legal compliance reasons, egg producers use specialist continuous inkjet equipment (such as the JET3up EP) to print a date on millions of eggs every day.

- CIJ is a particularly suitable printing process on egg production lines since it works well on curved surfaces.

- Timber yards and producers of building materials and other industrial goods often need to mark specifications onto the materials so they can be identified by retailers and tradesmen.

- Pharmaceutical companies need medicines to carry information – not only to prove production dates, but also to guarantee authenticity.

A LEIBINGER CIJ printer for every application and budget

One of the advantages of choosing LEIBINGER is that we offer a wide range of printers that cover virtually all possible production needs.

Production environments vary, requiring technical adaptations that promote productivity. These adaptations have enabled us to produce specialist models of CIJ printer.

Problems with dust and dampness

For example, in industries where there is dust or moisture in the atmosphere, LEIBINGER printers employ a special innovation. Pressurised air in the print head ensures dust does not get into the mechanism and cause problems. This means our CIJ printers can keep running when many others may clog up and need cleaning.

Equally, some industries operate by stricter hygiene regulations. The food industry, for example, needs to wash down all equipment at regular intervals. So we created the JET3up PRO with IP65 compliance. It is both waterproof and dustproof, giving our customers a specialist solution that meets their needs.

Faster production requirements

When speed is important, we have CIJ printers that can boost production efficiency by 30% by printing at speeds up to 800 m/min. The JET Rapid is a good example of this.

Smaller nozzles for fine printing

Need to go small? We even have a printer specially designed for manufacturers of smaller items, such as electronic components. The JET3up MI provides excellent print quality with a 35µm nozzle that enables printing at a font height of just 0.7mm.

High-contrast legibility

If you need to print onto dark surfaces, there can be a problem with legibility. We have provided a neat and cost-effective solution by creating CIJ printers like the JET3up PI, which work with pigment based inks. With a unique agitation system that keeps pigmented inks constantly circulating, it enables the printing of high-contrast letters and characters that show up against the dark background.

Why talk to LEIBINGER about industrial continuous inkjet printers?

LEIBINGERhas built a reputation for quality and innovation over many years. With each machine manufactured from scratch at our Tuttlingen factory in Germany, we can guarantee the build quality of each one.

In addition, we offer some unique innovations in our printing solutions. Our Sealtronic® technology, for example, ensures that ink does not dry out when there are pauses in production. With many printers, this can be a problem because print heads need to be cleaned before work can resume. With the Sealtronic® feature, there is a closed loop function that prevents exposure to the air. The ink does not dry out, the print head does not become clogged. And the production line just keeps rolling without time-consuming start-up cycles.

LEIBINGER's experience of continuous inkjet technology has helped us develop a range of accessories that complement our printers. From easy-to-use control software to brackets and fixings for easy integration, we offer all the components of a reliable and cost-effective CIJ solution to suit all industrial applications. We have also built up a network of more than 150 authorised partners around the world so our customers enjoy not only high quality equipment, but also the service and support they need.

LEIBINGER CIJ printers

Industrial coding solutions

LEIBINGER CIJ printers: ideal for coding expiry date, lot numbers and variable data on almost any material. Choose LEIBINGER printers for non-stop productivity.