The essential role of coding machines

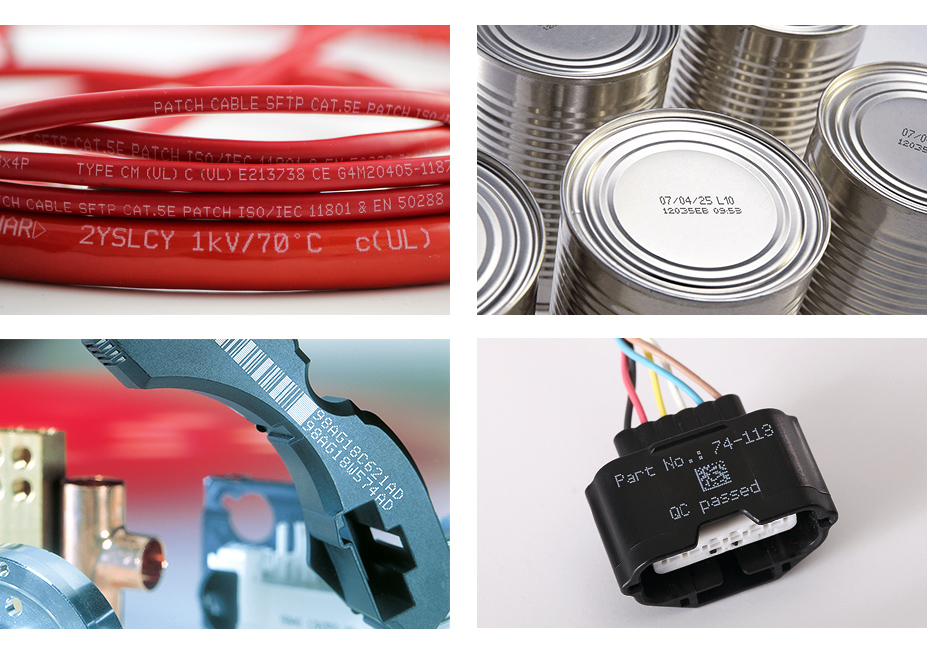

If you operate a production line, batch coding machines are essential. A batch printing machine attaches important information to your products by applying a mark or a code onto packaging or onto the product directly. This is a high speed, non contact process that places the coding machine at the heart of your business success.

Boost efficiency with a batch coding machine

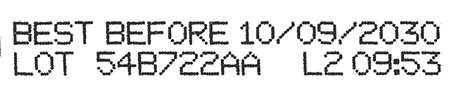

Your products are part of a sophisticated supply chain. At all points in the chain, products need to be identified, so they have a batch code or a batch number applied. That same batch code can also be applied to the outer packaging. This enables distributors, retailers and other parts of your supply chain to efficiently manage the movement of goods, and to manage product recalls if required.

Improve customer confidence with a date printing machine

If you work within industries such as dairy, food, beverages, pharmaceuticals or many others – you need date printing machines to apply a manufacturing date, batch code or an expiration date. This is important not only for the supply chain, but also reassures your customers of the freshness of the product.

How do batch coding machines work?

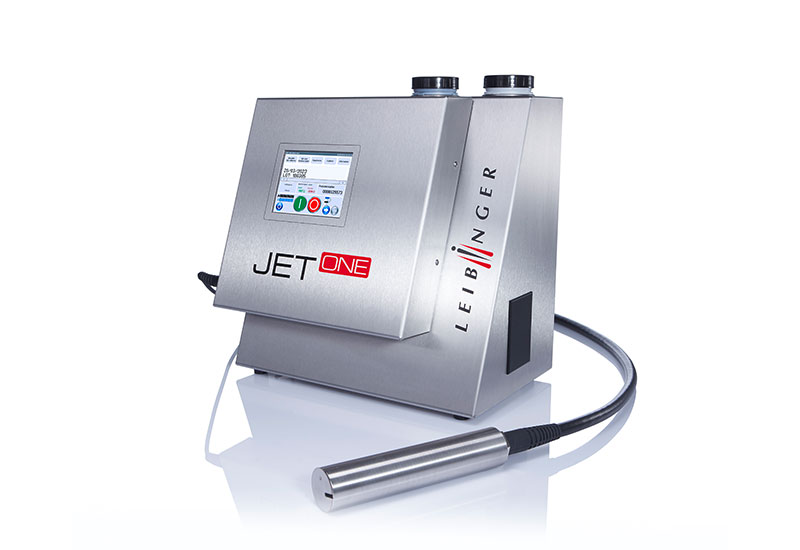

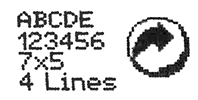

LEIBINGER batch coding machines use continuous inkjet technology. In this process, a continuous stream of tiny ink droplets is directed onto the print surface to form - depending on the deflection of the ink drops - fixed or variable marks, such as text, logos or bar codes.

What information can be printed?

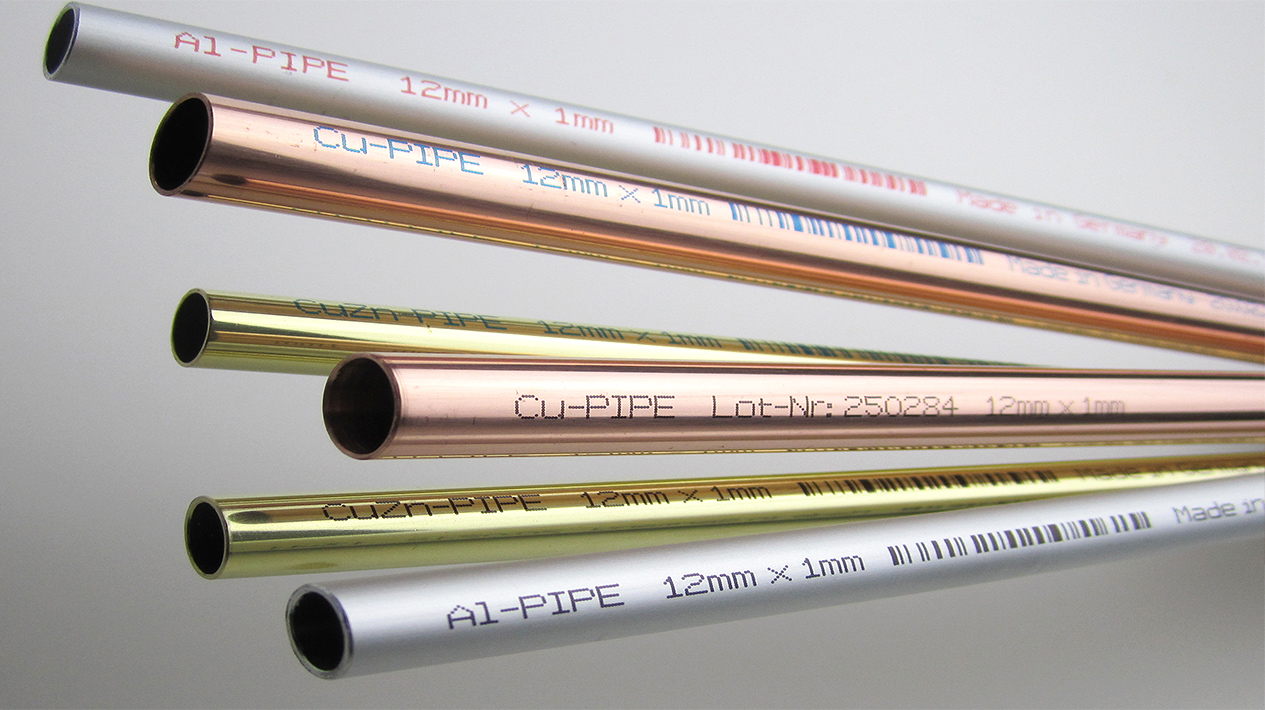

The information applied by a coding machine can be in a number of different formats. Sometimes, plain text such as food date codes is printed by a batch coding machine onto product packaging (or onto labeling). Alternatively, codes can be machine-readable: a barcode or QR code can be read by scanners (or mobile phones). In addition to these functional batch codes, coding machines can also apply your logos and other symbols. These are useful to remind customers of your brand.

In the food and beverage industry coding solutions need to apply batch numbers to many different items, from polypack bags and foil seals to glass water bottles to plastic bottles. As a leading manufacturer of coding solutions, we offer a range of batch coding machines that cover all food and beverage applications.

What inks are used by coding machines?

One of the benefits of LEIBINGER coding machines is that they can use a variety of different inks. If, for example, you are printing against a dark background, such as black plastic, you may need a high-contrast pigmented ink. If you are printing onto glass bottles, high-adhesion inks may be preferred because the surface is shiny and often carries a layer of moisture through which the ink must adhere.

Bottlers may also need washable inks (so old expiry dates can be washed off) and it is even possible to apply invisible printouts with a specialist UV ink. The choice of the right ink is a very important criterion when choosing a coding machine. That's why we create free print samples for your product. Just get in touch with us.

The benefits of LEIBINGER coding machines

LEIBINGER has been developing and manufacturing coding machines for many years, which enables us to bring some powerful benefits to customers:

Prevent production downtime

Batch coding machines can easily clog up when quick-drying ink congeals on the nozzle. Our unique nozzle closure system effectively prevents this. With Sealtronic, the ink circuit is closed airtight by an automatic mechanism during a production break and is opened again when it is restarted.

As a result, ink does not dry up and nothing clogs. Cleaning, whether manual or automatic, is completely unnecessary. LEIBINGER thus prevents a typical CIJ problem before it even occurs. The unbeatable advantage for productions: downtime of batch code printers due to dried ink is eliminated. Production becomes more efficient!

Easy integration

When installing a LEIBINGER coding machine, we also attach great importance to ensuring that this can be done quickly and that production can start up again quickly. In addition coding machines need to fit in with your production line. We offer a range of accessories to ensure that the integration of coding solutions is straightforward. Extra-short print heads or extra-long umbilicals are just two examples of our flexible printer equipment. Your LEIBINGER sales partner will be happy to advise you on your selection process.

LEIBINGER coding machines help to save energy

Each LEIBINGER coding machine works draws only 20W. In addition, we minimize the amount of solvent and ink used with a thermal barrier to separate the ink circuit from the electronic components. Keeping ink cool means less evaporation. And of course, Sealtronic technology reduces solvent evaporation by not exposing the ink to air.

A wide range of machines

Different industries have different requirements. So one of the main benefits of using LEIBINGER is that we have a wide range of coding machines. Whatever your need, we have the perfect batch coding machine for you. Take a look at the list below and see if any of these requirements apply to you.

A coding machine to suit all your needs

LEIBINGER works with many different customers – so our printers are designed to meet their specific needs. To see which coding printer from our wide range is the best solution for you and your production line, see the list below.

About LEIBINGER

Whichever coding machine you choose, you are assured of LEIBINGER quality and global support. We are a family-owned company that has built a global reputation for reliable and efficient marking solutions.

Every LEIBINGER coding machine is built at our factory in Tuttlingen, Germany, so we can check the quality before it goes to the customer. We also have a network of LEIBINGER experts in all geographies. This means that, wherever you are, there is someone nearby to help advise on purchases or to maintain and service your date coding machines.

LEIBINGER coding machine

Benefit from 5 years of no maintenance

Batch coding, date coding or printing of lot numbers: IQJET coding machine redefines the market standard for autonomy and reliability in coding & marking.