Date coders are pieces of equipment used on production lines to print date codes. Typical date coders are continuous inkjet printers that apply fixed and variable data to products and packaging during ongoing production. Date codes – whether on products, packaging or labels - are useful because they show the customer that products are fresh. But the date coding of products such as food, drinks and medicines and pharmaceutical products is also required by law around the world.

What do date coders print?

Typical/common date codes include:

-

best before date

-

expiry date / expiration date

-

use-by date

-

manufacturing date

Which of these dates are printed by a date coder depends largely on the product type, country requirements and company guidelines. A batch/lot number is usually applied together with the date codes.

When used alongside the lot number, marking date codes also helps toward internal tracking. The codes carry all relevant information, and can be printed onto the outer package as well as the product itself.

Applications of time & date coding

Date coding is used in many different fields: pharma, automotive, electronics, cabling and cosmetics. Therefore date code printer systems have to be versatile enough to cope with a wide range of products in different types of package, using different kinds of packaging material. The two most common uses for date coding are in food and beverage applications.

Expiration date printing in the food industry

A date coder is usually positioned on the line to mark each batch of products as they go through with the best before date, a lot number and often also with the date of production or manufacture. Whether these are ready-made meals, boxes of cookies, or glass jars, they all need codes.

Mostly, these are required by law but, at the same time, they also assure the customer of freshness and quality. When printing these codes, it is important that the date coder offers an ink that is legible and with high-adhesion quality. In addition, the date coder has to keep up with the speeds of the production line.

Date coding in the beverage industry

The speed also plays an important role in the selection of the date coder in modern beverage bottling plants. High speed CIJ printers mark expiration dates on glass bottles, PET bottles and beverage metal cans at up to 2,644 ft/min (800 m/min).

In addition bottles and jars can present a challenge, if temperatures are low because a layer of condensation is often present. Our printers address this challenge by marking with a high-adhesion ink to ensure successful operation against condensation.

A small character CIJ machine may be required to work in small areas such as bottle caps. On some surfaces, such as dark glass bottles, a pigmented ink may be used, set against the dark background, for additional contrast.

How LEIBINGER date coders ensure high productivity

What kind of date coder do you need? A business needs to compare the price and capability of each coder. What technologies do you need? What price should you pay? Will you need to request special features? Make sure that you don't have to pay extra for every function and that the printer is of high quality. Balancing cost against performance and service is key to making the right decision, and there is a list of possible models further down the page.

Avoid downtime!

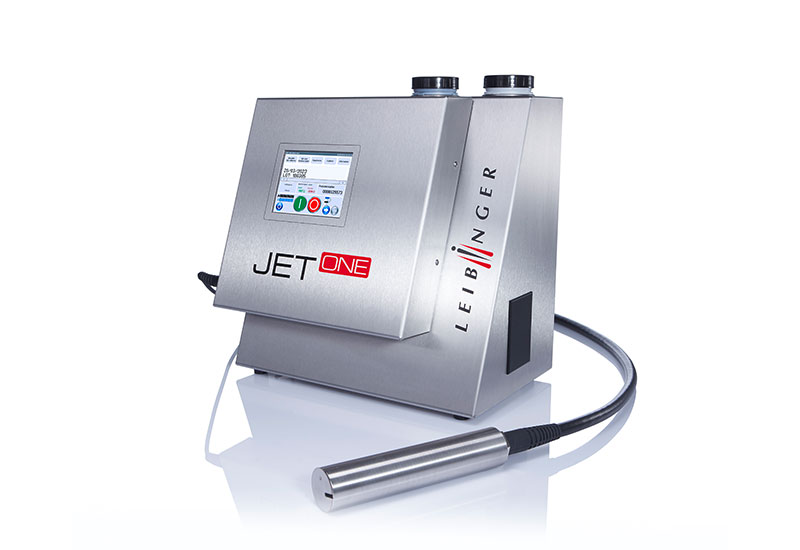

Productivity is strongly related to printer performance; the cost of downtime can be high and the date coder can be a weak point. But not with LEIBINGER. The Sealtronic feature built into every LEIBINGER inkjet machine is a great way to keep productivity high because it prevents the print head from becoming clogged with dry ink.

When printing stops, the nozzle retracts and forms a closed loop, keeping the ink flowing inside the system and not exposed to the air. So you can simply set it going again without time-consuming cleaning. LEIBINGER CIJ coders are always ready to print.

Easy integration into production lines and intuitive operation

To keep site productivity high, you need to minimize set up time. LEIBINGER printers can be set up quickly and will fit into the tightest of spaces. User friendly instructions on screen show how to set up the date code, meaning your staff don't spend too long managing the coders – just tap the button on the screen and they are free to get on with other work. We also provide a set of accessories: with LEIBINGER, you get the full package.

Versatility of use

Marking solutions need to be versatile enough to mark a code onto different surfaces, from the porous cardboard used on a box or other related packaging to smooth surfaces such as glass. LEIBINGER printers support all kinds of applications and our customers can choose from a wide set of inks.

IP65 protected printers

There are strict requirements for hygiene, which involve frequently washing down equipment. Many businesses choose IP65 protected printers, which are waterproof and can withstand the daily washdown operation.

Suggested date coding solutions

If you are just starting your search for the perfect date coding solution, we have a number of options for you. Take a look at the machines set out below:

Why LEIBINGER?

Since we are a family-owned company that has been specializing in continuous inkjet printing for three generations, we bring expertise and understanding of the challenges facing industries of all kinds. If you are looking for durability, quality and ease of use, don't worry – we're on the same page!

Reliable machines

Every LEIBINGER customer can rely on us for quality. The technologies are based on our expert knowledge in the field of precision engineering and built into our date coders, making them a dependable option for food & beverage and related industries.

Excellent global support

And, whichever country you are in, you are never far away from a LEIBINGER agent. Just submit a form or pick up the phone and they can provide immediate assistance.

The perfect combination

This combination of product quality and service excellence means LEIBINGER is set up as the ideal choice for coding and marking. If you have been looking for the perfect printer, contact us now!

Intelligent date coding

5 years without maintenance

The first intelligent coding system for food, beverage, pharmaceutical products and other applications: Choose LEIBINGER's IQJET to mark your products and packaging. The ideal date coder for your success.