LEIBINGER industrial inkjet printers and industrial inkjet technology

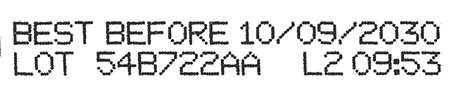

Industrial inkjet printers are used around the world for printing batch codes, best-before-dates, barcodes and other pieces of information on products and packaging. These marking systems have become a central part of manufacturing.

Why do we need industrial inkjet printing?

Products need to carry information. Sometimes it's a batch code or lot code to identify the product itself or its manufacturer. Or it may be a date code, to inform customers when it was made and when it should be used by.

To carry this information often means printing codes directly onto the product or onto the packaging in the form of text, logos, 2D code (like a QR code) or barcodes. These are read by machines or customers to identify the product during the industrial supply chain operation. The manufacturing process will include therefore a stage where a printer “marks” or “codes” the information as the product passes along the line.

Inkjet printing, thermal-transfer printing or laser?

A number of different printing techniques can be used. They all have different strengths and are used in different situations. The main technologies used are continuous inkjet printing, thermal-transfer printing and laser printing.

Continuous inkjet coding (CIJ printing)

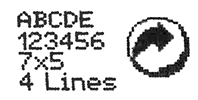

In continuous inkjet printing systems, a constant stream or jet of ink passes through a nozzle in uniform, single drops to deliver high print performance and efficiency. The charged droplets are then guided via an electromagnetic field to the precise location required to complete the code being printed in clear, readable condition.

Continuous inkjet inks are available with various properties to print codes with the ideal adhesion, color, and opacity for the product or package’s surface. You can therefore achieve excellent marking performance on all materials or substrates; a cost effective solution for marking quality codes in all industries.

Thermal-transfer printing

Thermal-transer printers apply high resolution codes onto packaging by melting a coation of ribbon. These systems are usually integrated in machines that need coding on flexible films and the print is in direct contact with the product. They are to be distinguished from thermal inkjet printers, which are a type of drop on demand inkjet system with print heads that offer high print quality.

Laser Date Coders

In contrast to an inkjet printer, a laser marking machine uses a focused beam of light to etch or physically alter the top layer of a substrate. The beam of light is steered by two mirror galvanometers that direct the laser beam in two planes, creating the date code on the product or package surface.

Which industrial inkjet printers are right for you?

The technology and the model that you choose depends on your budget, your needs and your production line. The following three models from LEIBINGER have different levels of features, giving them different price points. This means LEIBINGER quality is affordable to all manufacturers and production facilities of all kinds:

JET2neo

The mid-range printer for all standard inkjet marking and coding applications, printing up to 1,777 characters/second on three lines. more >

JET3up

Advanced, feature-rich CIJ printer to handle the most complex and challenging coding and marking applications. Prints a maximum of five lines and with speeds of up to 400 m/min or 1,300 ft/min, respectively. more >

...or do you need a specialist industrial inkjet coder?

Many industries have specific needs, which require their industrial inkjet printers to have certain additional features. This is why LEIBINGER has also developed the following specialist continuous inkjet models in its range. Whatever business you are in, we have a printer offering for you.

JET3up PI

Advanced, feature-rich continuous inkjet printer specifically designed to handle high-contrast pigmented inks for maximum legibility on dark surfaces. more >

JET3up PRO

Advanced, feature-rich continuous inkjet printer with IP65 protection to meet high hygiene requirements of manufacturers in the pharmaceutical and food industries. more >

JET3up MI

Advanced, feature-rich continuous inkjet printer with 35µm or 40µm nozzle for micro printing in the smallest areas. more >

JET2neoD

Specialist mid-range continuous inkjet printer designed for industrial applications. Provides maximum productivity and quality in dusty operating conditions. more >

JET Rapid Wire

Specialist high speed continuous inkjet printer, designed for high speed applications printing cables, pipes and wires at up to 1,000m/min. more >

JET3up EP

Specialist egg-marking continuous inkjet printer designed to bring maximum productivity to egg producers. Optional with IP65 protection class. more >

Benefits of LEIBINGER’s industrial inkjet technology

No more blocked print heads!

Every LEIBINGER industrial inkjet printer comes with an essential feature: Sealtronic. This is important because the fast-drying inks used can quickly clog nozzles in print heads when there is a pause in production that allows the ink to come into contact with air.

Our unique Sealtronic technology retracts nozzles, closing the ink loop and preventing it from drying out in the print heads. When you're ready to restart the marking process, the nozzle extends out again and you can start printing as before. No cleaning cycles, no unnecessary downtime on your production lines.

LEIBINGER inkjet printers also benefit from being able to use all kinds of inks, including UV, high-adhesion and high-contrast pigmented inks.

Keep quality high, keep costs low

You need high resolution product marking on demand. But you don't want high costs or coding mistakes. LEIBINGER equipment is both a reliable and a cost-effective solution. Each device integrates neatly with production lines with control software that is easy to use, keeping personnel costs down and minimising human error.

About LEIBINGER

LEIBINGER is a family-owned company with a reputation for robust, high quality coding solutions. At its factory in Tuttlingen, Germany, virtually every part of our inkjet printers is manufactured and assembled. Also, every machine is checked before going to customers. It's our way of guaranteeing high quality in our equipment.

We also have a global network of partners. Highly-trained and knowledgeable, they are able to help advise which printing solutions suit your business, and to meet and servicing and technical needs you may have.

LEIBINGER industrial inkjet printers

The intelligent coding solution

Expiration dates, barcodes, lot numbers, variable data: Choose IQJET industrial inkjet printer to mark your products and packaging. Benefit from 5 years without maintenance.