It’s one of those big decisions. Do you use laser printing or continuous inkjet printing for your industrial printing applications?

The difference between the two technologies is well known, and there are strengths in both camps, but we would like to focus on three key comparisons:Cost advantages: which technology is cheaper to run in the long term?Health & safety: which is best for the people working at your business?Higher flexibility: which allows you to do more on different materials?

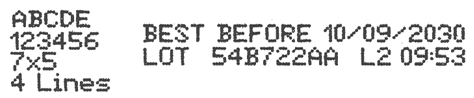

A typical scenario for continuous inkjet printing

As with all cost comparisons, it is important that you consider first of all the items that you need to print, the volume and the type of coding that you wish to apply. However, because many of our customers are involved in the production of large volumes of packaged goods, let’s assume the customer has a packaging line for packet soup. Such a packaging line normally works at a speed of about 250 packages per minute. Let’s furthermore assume that the factory works on a 2-shift basis with 8 hours per shift at 250 days per year. The packets get a 2-line print showing an expiry date and a batch number.

The cost advantage of continuous inkjet printing

When you put this all together, some interesting comparisons can be made – and there are of course pros and cons to each approach. Please note also that the data we have used is taken in good faith from what we know about the cost of our own LEIBINGER inkjet printers and publicly available data on laser printing.

The first point to make is that laser printers do not incur the ink and solvent costs associated with inkjet – a clear advantage of using laser-based systems. In our scenario, ink and solvent would cost €1,737/year. However, the investment cost of laser equipment (taking into account depreciation, annual interest rate etc) more than outweighs the consumables advantage.

When all numbers are taken into account, we estimate that the cost per print out using a laser printer is €0.009 cents. Using a continuous inkjet it is only €0.008 cents. A tiny difference? Over the course of a year, the difference is €616. If a producer is coding or marking many different products, this can mount up very quickly. Just imagine you have 10 or more different production lines…

What kind of inkjet coding printer delivers the greatest efficiency?

In the cost comparison above, we have taken a typical example using the LEIBINGER JET3up inkjet coding printer – but it is essential to make sure you have the right model for the right situation.

LEIBINGER produces a range of different ink jet printers and some models have different configurations and capabilities that make them suited to different tasks and production environments. For example, the JET2neoD industrial printer uses pressurised print head technology to prevent small airborne particles interfering with the print nozzle, which is particularly useful in dusty environments such as cement factories or in baked goods production, and the JET3up PRO is IP65-compliant – and therefore to withstand the regular washing down that is required as part of the daily hygiene routine at food producers.

Health & safety considerations of CIJ printers v laser printers

One of the most obvious differences between the two technologies is the fact that laser printing creates toxic fumes – and therefore must be fitted with an extraction system, and operators must use special eye protection. This clearly adds to the cost of that approach, but we also need to consider health & safety needs. Staff working with CIJ printers are not exposed to dangerous fumes.

Flexibility

Although there is a significant cost advantage to continuous inkjet printing over laser printing, many manufacturers and packaging lines choose it because of its flexibility. A single inkjet printer can be used to apply codes, symbols, or text onto virtually any surface by using different inks. High-adhesion inks can be used, for example, in scenarios where the surface is shiny or moist (such as the beverage bottling industry, where expiry dates need to be applied to bottles) or pigmented ink can be used when high-contrast colour is required against a dark background. Washable inks can be used (eg for re-usable glass containers, where new expiry dates need to be printed each time and the old ones washed off) and it is even possible to apply invisible printouts with a specialist UV ink.

Whereas different laser systems need to be acquired for different surfaces (eg plastic parts, glass bottles, aluminium cans), the same single LEIBINGER JET3up CIJ printer can be used for anything in any industry. Also bear in mind that non-contact CIJ printing is suitable for delicate surfaces that may be damaged by the action of some types of laser.

In addition, CIJ printing systems are highly mobile, whereas laser printers require extraction systems that are more difficult to relocate if the layout of the production line changes.

Beverage >>>

Meat, fish, seafood and poultry >>>

Cereals, flour and baked goods >>>

Convenience products >>>

A solution for all environments

In addition to the range of inks used and materials printed, LEIBINGER offers a range of accessories that make installation easier. CIJ printers are not only more cost-effective, but they are also safer and more mobile and offer a flexibility and ease of use that laser printers cannot replicate.

JET2neoD

Don’t let the dust choke your productivity

Specialist mid-range CIJ printer designed to provide maximum productivity and quality in dusty environments. more >

JET3up

The advanced CIJ solution

Advanced, feature-rich CIJ printer to handle complex and challenging coding & marking applications. Prints 5 lines. Performs at speeds of up to 10 m/s. more >