Production lines are tough places. They are not designed for comfort, but for efficiency. The aim is to maximise the amount of product that can be processed, built, assembled, or packaged every hour. And there is very little room for error.

As a result, everything has to keep running smoothly and downtime has to be kept to a minimum. But the production environment is often extreme for a number of reasons. This is no place for thermal transfer: only continuous inkjet will do and even those CIJ systems used for coding and marking can find it hard to cope.

Let’s see what this marking equipment has to face – and how it rises to the challenge...

Coding and marking when the temperature rises

Extremes of temperature are common in production facilities. But when products are being marked or coded in a warm environment, there can be ink problems. Solvent-based ink - which is often essential to mark clearly onto non-porous surfaces – evaporates quickly even at low temperatures. This is usually an advantage since ink needs to dry quickly, but when the temperature rises, solvent use can quickly become uneconomical.

One answer to the problem is EcoSolv, a technology developed by LEIBINGER that uses solvent recovery. According to research data, inkjet printers using EcoSolv use up to 50% less solvent than would normally be used otherwise.

Another problem is presented when extreme heat is used after printing. For example, how can a printed symbol or code withstand the 1000ºC heat of a furnace used to fire ceramic objects? LEIBINGER has developed an ink with heat-resistant particles that remains legible at these impossibly high temperatures.

Why production managers can relax with cold drinks

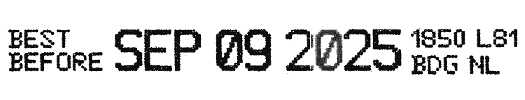

Most producers, however, deal with much lower temperatures. But the frozen food industry and bottling plants in the beverage industry face a different challenge altogether: condensation.

When surface water builds up on the cool surface of a bottle or on food packaging, it makes it much harder for the ink to adhere well. The solution is to employ high-adhesion inks. LEIBINGER has inks that are specially formulated for such an environment, which means that expiry dates and other marks can be quickly and reliably applied to surfaces despite the layer of condensation. Even more importantly for production managers, LEIBINGER inkjet printers are designed to use a wide range of inks, so a single investment in a LEIBINGER printer can be used in a variety of environments: simply change to any other ink in the LEIBINGER ink portfolio.

Eat my dust...

Some production lines are cleaner than others. Inevitably, factories that deal in finely powdered material – anything from flour and coffee to cement – have a problem with dust. Tiny airborne particles mingle with the solvent-based ink and can rapidly clog a CIJ printer or labeling system, unless there are measures in place to prevent it.

For customers who have to deal with printing in dusty environments, LEIBINGER has a trick up its sleeve. Specialist inkjet models (for example, the JET2neoD industrial printer) use pressurised print head technology to prevent dust interference, while the cabinet itself has a sealed back panel and housing ventilation to prevent ingress of dust. Even when printing onto a dusty surface – such as freshly sawn wood – these printers continue as normal.

Can a coding and marking system be truly waterproof?

Sometimes they have to be. One key consideration for food manufacturers, for example, is the need for hygiene and compliance with cleanliness standards. This often involves the regular deep-cleaning of the production environment – including any coding and marking system in it – after each shift. And that means LOTS of water.

But to a LEIBINGER JET3up PRO continuous inkjet printer, this is no problem. The JET3up PRO comes with a completely sealed unit that is IP65-compliant, and therefore able to cope with a regular cleaning. Not only that, the Sealtronic technology it uses means that it can start up again quickly after the washing down.

The need for speed

One of the biggest challenges of effective coding and marking is the speed at which is has to happen. It is a high-pressure environment where often thousands of products and their packaging need to be marked every hour of every day. For this to happen, a printer has to do two things: maximise speed and minimise downtime.

LEIBINGER CIJ printers are naturally designed to cope with fast-moving production lines. Able to print a moving object “on-the-fly” they are perfectly suited to the task and use fast-drying inks that enable the product to move quickly onto the next part of the production line. The coding and marking printers are seldom the bottleneck. But when customers demand even more speed, we even have more specialist machines, such as the JET Rapid printer, which can print on a wide range of materials at up to 800 m/min.

However, speed matters little if the production line sits idle for too long between cycles. Some inkjet coding printers delay the start-up of the production line because clogged print heads need to be cleaned before the start button can be pressed again. On LEIBINGER printers, our Sealtronic technology prevents the print head from clogging. As soon as printing stops, the nozzle automatically seals itself from the air, and allows liquid ink to continue to circulate. Nothing dries out, and the printer is ready to go again as soon as you are.

Beverage >>>

Frozen food >>>

Coffee and tea >>>

Building, construction and garden >>>

A solution for all environments

Coding and marking is an important part of the production process and varies enormously between applications and industries – but by providing a range of specialist marking systems, along with different inks, useful accessories, and some unique technology, LEIBINGER helps customers to print productively in all situations.

JET2neoD

Don’t let the dust choke your productivity

Specialist mid-range CIJ printer designed to provide maximum productivity and quality in dusty environments. more >

JET3up PI

A pigment printer that is a contrast from the rest

Advanced, feature-rich CIJ printer specifically designed to handle high-contrast pigmented inks for maximum legibility on dark surfaces. more >