Everything producers need to pay close attention to and how battery coding can be performed efficiently

The market for electric mobility is picking up speed. In 2021, 4.8 million new electric cars were registered worldwide – and this trend is increasing exponentially. Many new production sites for individual components or for vehicle assembly are being opened or are currently being planned.

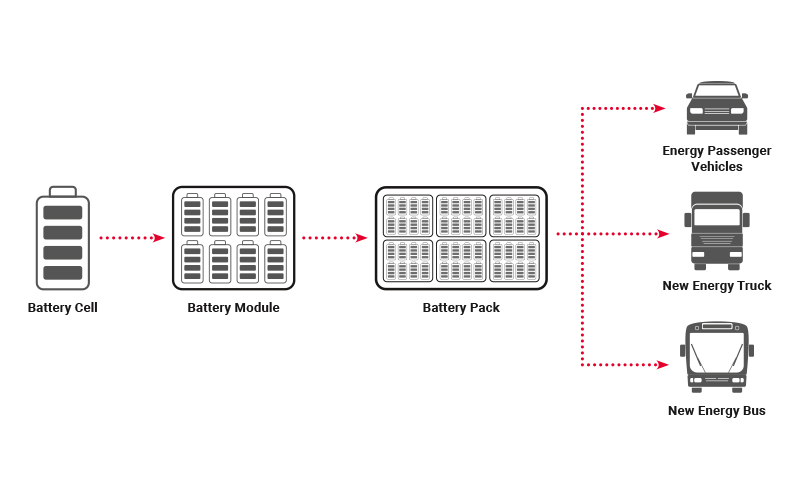

In this blog, we focus on the elementary component of every electric vehicle: the battery. Each battery in an electric car consists of numerous battery modules, which in turn consist of many individual battery cells. Depending on the model, a car requires about 10,000 individual, mostly cylindrical battery cells - – and each cell needs to be coded for complete traceability.

Here, you’ll find out everything you should consider when directly coding batteries, e.g. with a barcode or a LOT number, and how this can be performed efficiently in production.

To avoid damage to the surface of the battery cells: Coding with ink

It is especially important to note that the surface of a battery cell should never be damaged during the printing process. For this reason, laser coding is out of the question as a coding solution. Only ink-based systems can be used.

Among the ink-based systems, and after taking all requirements into account, the choice usually falls on continuous inkjet technology. For battery factories, so-called “gigafactories”, it is proving to be the fastest, most flexible, and most cost-effective method available.

The convex shape of a battery cell and implications for printing

The majority of lithium-ion or cobalt battery cells are shaped like a cylinder, i.e. they are convex. Rarely are angular battery cells used in electric vehicles Therefore the coding system needs to be able to apply the lettering in a clearly legible manner despite the convex shape. Since CIJ coding can print entirely without contact, the shape of the product to be printed does not matter. The ink drops fly through the air in milliseconds and land in such a way that the imprint is clearly legible despite the cylindrical shape.

What is Continuous Inkjet Technology (CIJ)?

In a continuous inkjet printer’s printhead, an ink jet continuously shoots through a tiny nozzle towards a catcher tube – the jet is broken down into up to 120,000 individual drops per second (!) by a transducer. During printing, two deflection electrodes change the trajectory of individual drops. These land as an image dot on the product surface and dry within a second. Point by point, fonts, graphics, barcodes, and data matrix codes are created – at a printing speed of up to 1,000 m/min.

Use of a CIJ printer in the production line of a battery factory

A clear text (LOT/batch number) and often also a barcode have to be printed on battery cells. For this purpose, the printer needs to be integrated into a system in such a way that it is automatically controlled by the main system. The correct print data is then sent to the printer via an interface.

Coding can be done “on the fly” – i.e. during ongoing production. In this case, the cylinder batteries are individually moved past a printhead on a conveyor belt and coded during the process. Often, the batteries are also moved past the printhead by a robotic arm and printed. If the printhead is also moved by a handling system, the marking process can be twice as fast as it would be without handling. With the extremely high number of battery cells required, it is essential that the coding process be highly efficient, automated, and therefore cost-efficient.

Cleaning of the printhead should never be neglected - or simply put your trust in Sealtronic technology!

In today’s highly automated production environments, reliable production equipment is of utmost importance. Staff deployment and downtimes for maintenance are cost drivers and affect productivity. Although coding systems are only a small part of a production line, they are indispensable. It is therefore essential to have this production step on the radar as well: because if the coding does not work continuously, the entire production comes to a standstill. Conventional CIJ printers are notorious for the issue of dried ink in their printhead – a fiasco in the case of a hard-to-reach printhead. The dried ink prevents the printer from starting up, or the print on the batteries is not clearly legible because the clogged nozzle in the printhead results in unclean printing. Cleaning must be done manually directly at the printhead, resulting in a long production downtime. Together with the rejects from incompletely coded batteries, this can have a devastating effect on productivity. Well-known manufacturers are coming up with solutions to this typical CIJ problem, but what most have in common is that solving the issue requires accessing the printhead to clean it, which causes downtime and becomes a time-consuming ordeal. Coding and marking expert LEIBINGER eliminates this typical inkjet problem before it even occurs. Its Sealtronic nozzle sealing system prevents the printer nozzle from becoming clogged, thereby avoiding the downtime associated with printer cleaning. This largely eliminates the regular cleaning required with many systems. High-quality CIJ printers can also be controlled remotely and/or monitored via a cloud.

Sealtronic: Why clean something that doesn’t get dirty in the first place?

During production breaks – for example at the end of a shift or at the weekend – Sealtronic technology retracts the catcher arm in the printhead and hermetically seals the nozzle. The CIJ printer’s continuous ink jet is therefore not interrupted, but merely sealed airtight and the ink then continues to circulate in the closed system. This effectively prevents the nozzle from drying out.

Halogen-free inks required

Halogen-free inks are often a requirement for battery coding, due to current standards and norms, for easier product recycling and as a user safety feature since fewer toxic fumes are released. Halogen-free inks are now standard on the market and available for many coding systems. Make sure that the inks you select exhibit excellent adhesion properties and are resistant to abrasion and overprinting. We strongly recommend sample printing in advance. LEIBINGER will be happy to test-print your battery cell – free of charge and without obligation – with the ideal ink to meet all your requirements.

Continuous inkjet printing also for the subsequent steps in battery production

Several individual, generally cylindrical, battery cells together form a battery module. 10 to 15 such modules* are then assembled in a battery-accumulator package, which is installed as an energy supplier for an electric motor. In addition to the battery cells, the modules and the entire battery pack also must be coded. Here too, CIJ coding is an economically attractive solution, especially since the use of one coding technology leads to advantageous synergy effects.

* Numbers vary depending on model

Conclusion: CIJ coders are a clear step ahead in battery coding in terms of compatibility and flexibility

The coding of many components in electric vehicles is mandatory. A coding solution is therefore indispensable. In the specific case of battery cells, it is important to note that these cannot be coded with a laser, since this could damage their surface. An ink-based coding system should be able to cope with the mostly convex shape of the battery cells, be fully integrated into the production line, be reliable and low-maintenance to avoid downtimes, and work with very adhesive, mostly halogen-free inks. CIJ printers meet all these criteria. If you also consider TCO calculations, the choice, objectively speaking, most often falls on a CIJ coder in favor of overall productivity.

Here, you can find out more about LEIBINGER continuous inkjet printers for coding electric car batteries. Contact us for a no-obligation consultation and free sampling!

JET2neo

The productivity machine

The mid-range printer for all standard marking and coding applications, printing up to 1,777 characters/second. Prints up to three lines. more >

JET3up

The advanced CIJ solution

Advanced, feature-rich CIJ printer to handle complex and challenging coding & marking applications. Prints 5 lines. Performs at speeds of up to 10 m/s. more >