For most people, counterfeiting is a problem that affects the fashion industry. While this is damaging to the brands themselves and their reputation, it does not actually put consumers in danger. When you replace a genuine automotive part with a fake, however, it could be serious.

Counterfeit producers reduce their costs to a minimum in order to keep their price down and compete with the genuine brands, whether they are manufacturing exhaust systems or steering wheels. They therefore often fail to observe safety requirements and use sub-standard materials. This is what makes automotive marking so important.

Automobile parts manufacturers and the automobile brands themselves have a keen interest in curbing this through coding and traceability. Find out more about the reasons and how LEIBINGER coders can help you with marking of the automotive components used in vehicles.

The role of automotive marking

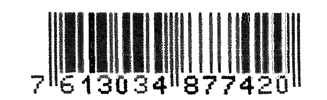

The ability to identify a genuine part is essential for everyone in the automotive industry, from customers to dealers and mechanics. One reliable way of doing this is using automotive part marking systems (also known as automotive part marking, direct part marking, or VIN marking systems) to provide a barcode which can be scanned in order to prove the part is genuine. The marks (or 2d code) can be linked to any data: a vehicle identification number, a part number, date codes, or even a phone number.

This also has the benefit of traceability, showing suppliers how, where and when products are bought, used or returned. Marking automotive components has become a widely used solution both in order to protect against counterfeit products and to optimize the efficiency of the supply chain.

Industry-wide action against counterfeiting

CLEPA, the industry body for European automotive suppliers, has launched a traceability initiative called “Manufacturers against Product Piracy” (MAPP) to improve part traceability and combat counterfeiting.

Marking automotive parts with a data matrix barcode based on CLEPA's recommendation enables a manufacturer or an OEM to make vehicle identification numbers and part numbers available with a simple scan through oneIDentity+, CLEPA's own traceability system.

However, the traceability system only works if the 2D code or bar code is available for users and supply chain partners to scan – and this is where the power of inkjet coding machines comes in.

The benefits of part markings

The laser marking of vehicle identification numbers or the application of part numbers traditionally involves laser printing marks (or numbers, tags, logos or other identification marks) onto a label or the product packaging. However, what happens to traceability when the part becomes separated from that packaging during its lifecycle - for example, after it has been fitted on the car? How can you ensure that the vehicle you are repairing, or the second-hand vehicle you are buying is equipped with safe, high-quality components?

The answer is part markings. Direct part marking means that automotive manufacturers, purchasers, mechanics, and other supply chain partners are always able to check the authenticity of automotive components. Marking automotive parts with a vehicle identification number can be done with a laser marking system or a dot peen machine, but the marking solutions that best fit automotive industry requirements are marking machines like LEIBINGER CIJ printers.

Is the marking of automotive parts expensive?

In short, no. There is a wide variety of batch coding machines available, priced to suit your requirements and specific applications.

JET2neo: The productivity machine

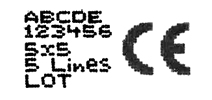

Within the LEIBINGER range, for example, many automotive manufacturers choose the JET2neo marking system as an affordable basic-level model. If you need to print up to three lines, it is great way to get started with applying of VIN marks for traceability or barcodes to parts, and thus protecting customers against counterfeits. To find out more about the JET2neo or to get a quote, see the product page here.

JET3up MI: Printing in the smallest areas

Some automotive components can be very small and require small type. The finer 35 µm or 40 µm nozzles used by the JET3up MI offer incredible legibility in the tiniest of areas with a font height of 0.7 mm, and make light work of more detailed coding and marking challenges.

Find out more about the JET3up MI here.

Also bear in mind that the cost of a coding system should be compared to the financial damage caused by lost sales of automotive components and reduced customer confidence. Counterfeit automotive parts are a problem and barcode printers provide an effective solution that will pay dividends throughout its life cycle.

How does continuous inkjet marking compare to other technologies?

Compared to other non-contact coding technologies (such as laser marking, dot peen marking or using a piezo or thermal inkjet marking system), continuous inkjet provides greater value and speed. Since production lines often operate at high speed, customers choose CIJ technologies over laser marking and other marking machines because they can operate at up to 800m/minute. This means many more automotive parts can be coded every minute by each of these permanent marking machines, reducing the total cost of traceability per item.

How do you ensure fast, effective automotive marking?

The production process needs to be efficient and need to run without interruption. Some coding printers can cause a problem because the quick-drying ink used in marking can become clogged around the print head. This can cause delays in direct part marking when the print heads have to be cleaned before the manufacturing production line can start running again.

However, LEIBINGER non-contact printers prevent any delay to automotive part marking with the application of its Sealtronic technology, which prevents the ink being unnecessarily exposed to the air – which means no clogging, no extra cleaning, and no unnecessary downtime for the manufacturer or OEM.

In addition, integration of LEIBINGER printer solutions with your existing manufacturing management system, makes it easy to handle different print applications on different products and to facilitate the changeover between applications.

A range of inks for a range of surfaces

Automotive parts come in a number of shapes and sizes and are composed of many different materials, requiring the application of marks onto steel, glass and a number of synthetic materials. However, this is not a problem for LEIBINGER marking equipment since we can also provide the automotive industry with a variety of different inks that adhere to any surface, marking beautifully legible VIN marks, date codes, tags or other identification marks. We also provide a service where we can provide a sample to prove how well the text adheres - simply send us one of your parts, and we will print you an example!

JET3up MI

The finest print, the finest quality

Advanced, feature-rich CIJ printer with 35µm or 40µm nozzle for micro printing in the smallest areas. more >

JET3up PI

A pigment printer that is a contrast from the rest

Advanced, feature-rich CIJ printer specifically designed to handle high-contrast pigmented inks for maximum legibility on dark surfaces. more >