Industrial printers are used for a million different purposes. Many industries require a continuous inkjet industrial printer to mark products and packaging. If you need a coding and marking solution for your business, how do you get the most out of it?

Which industries and applications will get most benefit from an industrial printer?

Coding and marking equipment is in use on production lines around the world, from the United States to Uganda. Different industries use these printers in different ways, and in a variety of different environments. Label printers and tag printers are an expensive solution to mark products. Because of that we take a look at some of the types of business which are using CIJ coders as their printing solutions.

Packaged food

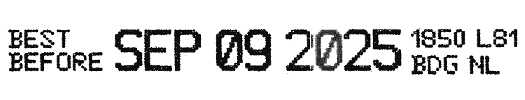

Modern families rely on packaged food, whether it is a loaf of bread or a ready-made meal. Continuous inkjet printers are used to print “best before” dates and other important information. Food producers are also constantly changing packaging formats or material in order to satisfy customer needs - so applications of printer equipment will vary. Therefore, batch and date coders need to be flexible enough to cope with printing on anything while delivering reliable, high-speed performance.

Beverages

Bottling plants can fill 100,000 bottles every hour, so the CIJ printers used must deliver high quality at high speed. LEIBINGER printers can add multi-line imprints such as date of manufacture, use-by dates, and batch numbers directly onto concave or convex parts of bottles, cans, tetra packs or labels.

Coffee, tea and tobacco

One of the key challenges of packaging and producing coffee, tea and tobacco is the dusty environment that it creates. Usually, this is bad news for inkjet printing as the dust interferes with the printing process. LEIBINGER printers, however, can be adapted with a pressurized printhead, where air pressure forces dust particles away from the print area, ensuring high-quality printing at all times.

Dairy

As with all food operations, hygiene is essential in the dairy business – and shelf life is very short. This means that the CIJ printers in use need to deliver top performance in order to get the products out of the door as soon as possible - but also that they enable the producer to comply with hygiene regulations. Dairy producers will typically spray-clean the entire production environment at the end of each working day or even between batches to maintain cleanliness. The CIJ printers in use must therefore have IP65 protection.

Frozen food

Not all industrial printers, certainly not label printers, can operate at extreme temperatures – but frozen food makes it a necessity. LEIBINGER coders can be adapted to perform reliably at very low temperatures, enabling frozen food manufacturers to keep output high.

Eggs

The world of egg production is a specialist field of food production. In countries such as the United States, producers need to comply with legislation, printing batch codes and “use-by” dates on each egg - and often on the packaging too. The non-contact nature of CIJ printing is well-suited to fragile products like eggs, and different inks can be used to ensure maximum legibility against brown or white egg shells. Inkjet printers will of course need to be integrated into your egg production infrastructure. Companies like LEIBINGER work closely with the Moba Group, ensuring that printers fit effortlessly into, and connect with, Moba and Diamond Systems. Instead of labels and label printers, a direct print via CIJ can also be applied to the egg boxes.

Detergents, homecare and cleaning

Hazardous products need to carry important information - which is often applied via continuous inkjet printing. Stringent international regulations can be easily met with industrial printing solutions, even when it means printing onto a variety of convex or concave product surfaces.

Pharmaceutical/medical

Few industries are as tightly regulated as pharmaceuticals and healthcare. Manufacturers are required to print codes on packaging, boxes and blister packs to permit traceability and protect against counterfeiting. Inkjet printers can be used to print fixed and variable data, such as the PPN code, or expiry dates and batch numbers. Inkjet printers can also be used in healthcare environments, for coding patient wristbands.

Industrial parts

Industrial processes often use thousands of smaller parts, all of which need to be identified and coded. Printing onto each part, using a barcode or data matrix code containing very specific encrypted data, enables traceability. Labels printer would have the disadvantage that the labels could quickly peel off small parts.

Building materials

Building materials come in all shapes and sizes, but CIJ printers are able to handle most challenges, from metal and plastics to wood and stone. Building materials - particularly products such as plaster and timber - can create a lot of dust, so specialist equipment with pressurized printheads are invaluable.

Electronic devices

As electronic devices get ever smaller, the demands on the coders used by device manufacturers increase. By reducing the nozzle size, however, printers can print with extraordinary precision. LEIBINGER printers start at a tiny 35µm - small enough to deliver excellent print quality in the smallest of print areas.

Wires, cables and pipes

Industrial printers are essential for manufacturers of cables, wires and pipes. Each length of cable or pipe needs to carry information to tell engineers and customers what lies beneath the cable sleeve, and this is applied - at very high speed. The specialist printer JET Rapid Wire created by LEIBINGER for the industry, can print 1,000m of cable in a single minute.

How to choose an industrial printer

There are many manufacturers of industrial printers, but be sure to choose one that offers the qualities that your industry demands. Apart from the special requirements mentioned above, a successful production line will need a printer that is:

- flexible enough to fit in with your production line

- robust enough to withstand a sometimes harsh production environment

- innovative enough to provide fast-start productivity

- reliable enough to last for years

All the above industries will find CIJ solutions to suit them. Here at LEIBINGER, we have options to suit everyone. Start by looking at our product portfolio.

JET One

It all starts here

Attractively-priced entry-level printer offering two-line printing on a variety of materials and featuring unique Sealtronic technology. more >

JET3up

The advanced CIJ solution

Advanced, feature-rich CIJ printer to handle complex and challenging coding & marking applications. Prints 5 lines. Performs at speeds of up to 10 m/s. more >