Pharmaceutical coding on vaccines

The reaction of the world's medical and pharmaceutical industry to the threat of coronavirus has been nothing short of heroic. Safe, effective vaccines have been developed and tested in record time and they are the only way that we are going to be able to end the pandemic. But there has also been great interest in the logistics of vaccine distribution. It is one thing developing a vaccine, but there have to be measures in place to ensure the right vaccine is sent to the right place and that medical staff know exactly what is inside each vial. The marking on each vial – provided by pharmaceutical coding – confirms the authenticity of the contents and other critical information.

The crucial role of pharmaceutical coding

When it comes to the development and rollout of vaccines, data is everything. The fundamental virological studies are conducted in the lab and promising vaccines are developed. But they cannot be used until they have been thoroughly tested – and even once they are approved, it is of the utmost importance to continue to monitor their use and their ability to protect people against disease. This is why - before, during and after roll-out – the code technology used to securely, legibly and cost-effectively number each vial with codes or bar codes is critical.

The code printing solutions used in the coding process apply UV inks to the crimp caps and the vials used to store the products. This means that researchers improve their understanding of which batch of vaccine was used on which patients and on which site in which area. Combining this code information with data on the subsequent health of the vaccinated (and unvaccinated) population paints a clear picture that can guide virologists towards ever better vaccine programmes. Better data means better results.

Coding COVID-19 rapid tests and PCR tests

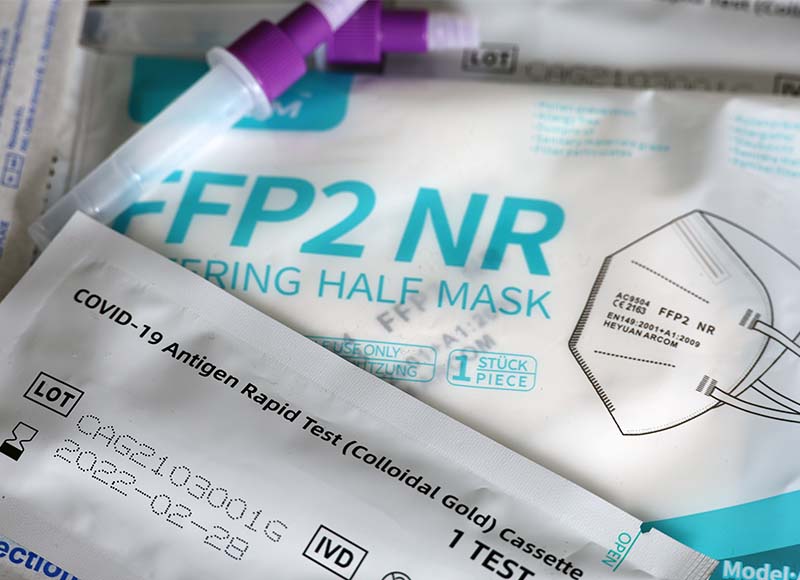

While the interest in recent months has been on the coding and marking of the vaccines, these are not the only pharmaceutical items relevant to the pandemic that can be coded.

The growing number of COVID-19 rapid tests or PCR tests also requires extensive marking onto packaging or direct marking on the tests with regard to authenticity, origin, LOT number, manufacturing date and expiry date. All of these are challenges for manufacturers that have to be solved with a competent coding and marking partner in accordance with legal regulations. At the same time, such imprints give the consumer confidence in an otherwise very uncertain time.

What can pharmaceutical coding be used on?

In the first few months of the pandemic, the supply of hand sanitisers and disinfectants could not keep up with demand. As supermarket and pharmacy shelves emptied, unscrupulous online merchants presented us with a problem, which inkjet or laser marking systems helped us to overcome. Not only were online stores sometimes selling at unfairly exaggerated prices, there was sometimes doubt over the authenticity of the product. The answer was to use printing solutions to apply codes and barcodes to all products and packaging (and even the supporting documentation that comes with the products). Customers were reassured by the code on the packaging that they were buying a reliable product.

Other products such as mouthwash – the protective qualities of which are much discussed but remain unproven – have also become of more interest as people seek to do what they can to avoid infection.

Whilst face masks and other PPE (protective personal equipment) are strictly non-pharmaceutical items, the same principle applies - and a code can be applied to any object, item or device. Printing codes and bar codes on the box or packaging with a LEIBINGER CIJ printer helps customers to know what they are buying and how effective it will be.

Challenges of coding and marking

There are business requirements of the pharmaceutical industry. Any commercially-minded company needs systems that enable it to operate efficiently and reliably, which is why LEIBINGER printers are designed with a combination of technology and high quality materials that meet their requirements for productivity and performance at the packaging and production site. One of a number of products we offer is Sealtronic print head technology, which minimises downtime of marking systems by preventing ink from drying in the nozzles of the printers. This technology helps each device to be more efficient – and ultimately plays a small part in supporting a more effective vaccination programme.

There are also many compliance regulations that govern the practice of coding and marking. If a company wants to use codes on packaging (whether boxes, cases or the vials themselves) of a product, it needs to abide by all rules. This is why LEIBINGER provides inks for its printers that offer compliance with US FDA and other organisations.

The marking system technology can also print a high-quality code or series of numbers on the box or packaging that show whether the vaccine is within its expiration date. This code is particularly important in preventing expired and therefore ineffective vaccines from being administered. One small device printing just one small code could save a life.

What accessories are required for effective pharmaceutical coding?

Inkjet coding services are a small but important part of the pharmaceutical production process - and it is important that it is efficiently integrated. LEIBINGER helps its customers to ensure this by providing not just a number of different packaging printers, but also a series of useful accessory products to make the packaging production line as efficient and productive as possible. And this will also contribute to the overall performance of perhaps the most important vaccination programme in history.

JET2neo

The productivity machine

The mid-range printer for all standard marking and coding applications, printing up to 1,777 characters/second. Prints up to three lines. more >

JET3up MI

The finest print, the finest quality

Advanced, feature-rich CIJ printer with 35µm or 40µm nozzle for micro printing in the smallest areas. more >