Wooden products or timber often need to be marked or coded with text, barcodes or logos. But how can you do wood printing legibly, cope with dusty environments and handle production breaks?

A print on wood machine that won’t let you down

As a material, wood has unique properties. Different types of wood have different strengths and qualities. The surface of the wood can be coarse or finely sanded. And of course different production lines need to code for different reasons, which brings enormous variety to printing on wood. Your print on wood machine needs to be one that meets your printing requirements exactly.

As one of the world’s premier manufacturers of continuous inkjet printers, used for non-contact printing onto all kinds of products around the world, LEIBINGER has been helping manufacturers and timber yards alike with their wood printing for many years. We have seen a number of factors that affect production in these businesses – these are the key wood printing issues to look out for.

How to print on wood with inkjet printer technology

One particular challenge in any factory where wood is sawn or cut, is the amount of dust in the air - which may have a profound impact on the ability to operate direct jet printers and print in wood. LEIBINGER technology gets round this problem neatly by providing pressurized print heads. This pressure forces tiny dust particles away from the print area, ensuring legible printing every time in the dustiest environments.

Another potential problem is that, when production is paused, most print heads become clogged with dried ink - which means time spent cleaning before you can start up again. Sealtronic technology prevents this happening by protecting the ink from exposure to the air – so you can start again immediately.

What is the information that needs printing on wood?

The information printed directly onto wood can include many things and is often variable (such as date of manufacture). It ranges from characters and text that are designed to give information to anyone reading it, to machine-readable formats such as barcodes and QR codes. In addition, company logos may need to be printed.

What surface are you printing onto?

Wood tends to have very absorbent qualities - especially when compared to other materials used in manufacturing, such as steel and plastic. This has to be taken into account for wood marking and coding. LEIBINGER CIJ printers provide extremely precise and legible printing with inks that are perfect for absorbent wood surfaces and wood substrates. Before we sell you a printer, LEIBINGER will advise you which ink is suitable and give you free print samples on your preferred wooden material.

Because we have experience in working with many different manufacturers and producers, we can advise on the best printing solutions for anything from lumber/wood composite and particle board to plywood. We can equally recommend the best way to print directly onto floor coverings, such as parquet or laminate, or floor skirting boards or even wood signage. Wood is also widely used in furniture manufacture, for which we also provide specialist coding and marking solutions.

See also special informations for these industries:

Building, construction and garden >>>

Furniture and toys >>>

How small do you need to go?

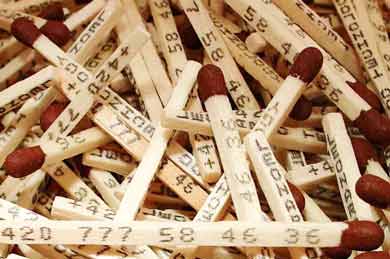

A direct jet wood printer can be used on items of all shapes and sizes - from bulky lengths of timber to finely crafted wooden products, such as toys or furniture. A key variable in the configuration of CIJ printers is the size of the nozzle. LEIBINGER printers can be configured to use nozzles as small as 35µm (as in the JET3up MI), which make it possible to print up to 5 lines at a font height of just 0.7 mm – small enough to put your logo on a matchstick! You can also print with a 32 dot font height and use multiple printers in combination, for example coding large prints across the entire surface of stacked wooden pallets.

What other tools do you need?

At LEIBINGER, we aim to provide a complete wood printing solution. This is why, in addition to reliable and innovative inkjet printing machines, we provide all the extra accessories you need to accommodate printing into your production line. We provide stands and brackets to physically integrate the printing units, and also offer other tools that enhance quality and production. These include monitors and sensors - camera systems that automatically check the quality of print and warn users if anything goes wrong. This rarely happens, but this safeguard means that faults can be ironed out quickly instead of having to reject a large number of incorrectly marked items. Overall, LEIBINGER is proud to deliver virtually anything needed by timber yards or manufacturers of wooden products – whether it’s a print on wood machine or advice, support and customer service.

JET3up MI

The finest print, the finest quality

Advanced, feature-rich CIJ printer with 35µm or 40µm nozzle for micro printing in the smallest areas. more >

JET3up PI

A pigment printer that is a contrast from the rest

Advanced, feature-rich CIJ printer specifically designed to handle high-contrast pigmented inks for maximum legibility on dark surfaces. more >