Every day, millions of eggs are farmed, packaged and consumed by hungry customers around the world. However, given the short shelf-life of the product, the production is subject to stringent health regulations. One consequence of this is that most producers need to code each individual egg with information that tells buyers and transporters about provenance and freshness at every stage of the supply chain.

Why industrial inkjet printing is perfect for egg coding

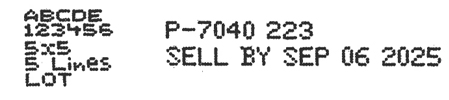

Many countries around the world already require standardized egg coding. Increasingly, producers are being required to print information directly onto eggs or egg cartons, such as a manufacturer code, the laying date or other production-related information. But egg coding can create significant added value for both the consumer and the producer even when the process is not mandated by law.

- Compliance with local regulations for egg coding

- Increased transparency and food safety foster trust among consumers

- Complete product and process traceability for producers and consumers

- Purchase-related information is passed on to the end consumer (e.g. farming conditions)

- Concrete differentiation between competitors (especially in countries without mandatory marking and coding)

- Retaining customers: manufacturer logos create recognition value and contribute to brand identity, especially in developing countries where eggs are sold individually and not packaged together

- Increased production efficiency

Why apply an egg code with a LEIBINGER inkjet printer?

Continuous inkjet printers provide maximum flexibility because they can be used to print fixed or variable information and, thanks to non-contact printing, different sized eggs are coded safely and reliably without readjusting the printhead.

Efficiency and compliance

We offer all producers a complete hardware and software solution, including FDA and EU-compliant food-grade inks, special egg shell inks, the optional IP-65 protection class for protection against dust and spraying water as well as the automated Sealtronic nozzle seal (integrated by default) to prevent ink from drying out in the printhead.

Legislation involving egg marking and coding can be complex. The European Union (EU) requires that they be marked directly with a producer code. In the US, the LOT number must be printed onto the carton or directly onto the shell. Markings on packaging are required in Canada as well. The import and export regulations of some countries also require codes.

With a LEIBINGER egg printer – powered by our printer software applications – you are able to comply with minimum disruption to your production. Designed to be easy to use, they operate at high speed providing excellent legibility on packaging or on eggshells of any colour. We also know that egg packaging can use a number of different materials and offer solutions that print effectively onto cardboard/carton, plastic, shrink wrap, foam or of course onto the eggshell itself.

Powerful software makes it easy to change text when required and the LEIBINGER service network means we can provide training, servicing and spare parts quickly wherever you are located.

Egg carton barcode or egg code directly onto the shell – CIJ can do both

It’s your choice! Text, codes or logos can be positioned anywhere thanks to the flexible printhead - which means anywhere on the egg itself or on the packaging that protects it. We have developed a specialist elbow printhead for the egg industry, which provides top-side printing of the eggs even in cases where the conditions in the egg sorting machine are very cramped.

Eggs and egg cartons >>>

A reputation for reliability

LEIBINGER equipment is 100% manufactured in our factory in Tuttlingen, Germany. This means we can ensure the quality of each and every machine. Egg producers cannot afford disruption caused by reliability problems. Our determination to help our customers towards the highest possible levels of productivity has led not only to our reputation for solid reliability and excellent service, but also to the development of technologies such as Sealtronic, which ensures that production does not have to wait for printer nozzles to be cleaned between sessions.

How to integrate egg coding into your egg production facility

LEIBINGER printers are compatible with Moba and Diamond egg sorting and packaging machines (Moba Group). They are shipped with all interfaces, connections and cable sets, allowing for quick and easy plug-and-play integration. Complete integration into the egg sorting machine provides enormous advantages, such as automatic application of any changes in printing data for all printers in the system and automatic updates to the expiration date.

LEIBINGER also provides a range of accessories that can be used to improve the efficiency of your production. We provide sliding stands that make it easier to position equipment where you need it, and we also offer our V-check Vision system, which automatically keeps an eye on print quality. If any degradation in quality is spotted, operators are notified immediately – further helping to avoid expensive downtime.

JET2neoEP

Millions of eggs, one coding solution

Specialist mid-range CIJ printer designed specifically to maximize production and quality for egg producers. more >

JET3up EP

The ultimate egg-marking solution

Advanced, feature-rich CIJ printer designed to bring maximum productivity to egg producers. Optional with IP65 protection class. more >