Printing codes, logos and text on cables and wires is a high-speed task, and the wire marking equipment you use has to be reliable. LEIBINGER continuous inkjet printers specialize in imprinting and marking for cables, pipes and wires because they offer precision, high reliability and an extra High Speed Line with special wire printers. That means text, logos and codes are legible – and your production line is efficient.

Faster than a lion can run!

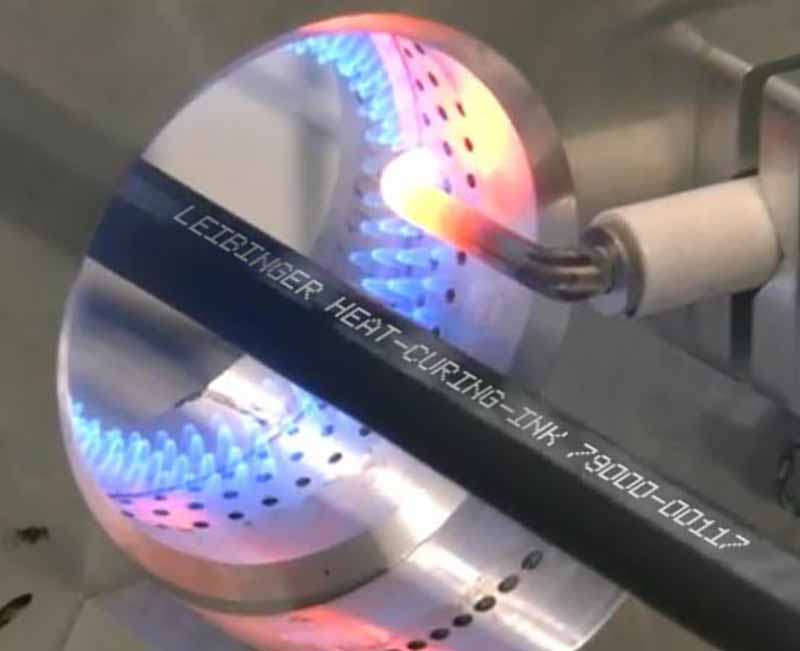

Cables and wires are extruded at such high speed that it is not uncommon for the process to be slowed down by the need to print. With specialist LEIBINGER printers such as the JET Rapid Wire, speeds of up to 1000 m/min are achieved – so production is not impacted at all. But high speed does not mean a compromise on quality: our printers deliver a clean, durable printout, with fixed and variable letters and numbers clearly legible. Immediately after printing, special inks ensure maximum adhesion and abrasion resistance on all common product materials.

Wire marking – without interruption

Our customers need maximum productivity, and therefore expect our solutions to offer the best in terms of quality and reliability. 100% German-made under one roof in our factory, our CIJ printers are the epitome of reliability. Coding and marking happens at high speed and downtime is not acceptable: this is why our customers trust LEIBINGER to keep the production line moving.

Wire marker solutions are enhanced by Sealtronic print head technology. The problem with continuous inkjet printing is that the ink has to dry fast – as soon as it hits the printing surface. So any pause in production results in dried ink and blocked nozzles. But not with LEIBINGER’s unique Sealtronic technology.

When production stops, the nozzle automatically seals. That means that nothing dries out, so you can start again immediately without cleaning or rinsing cycles. Production lines need to keep moving in order to maintain the profitability of your cable and wire business. And instant initialization also means instantly reliable printing without degradation of quality. Also, the viscosity of the ink is unaffected. And you use fewer consumables.

In summary, wire markers from LEIBINGER help you to mark and code wire faster. Wire coding is clearer, with every label easily read.

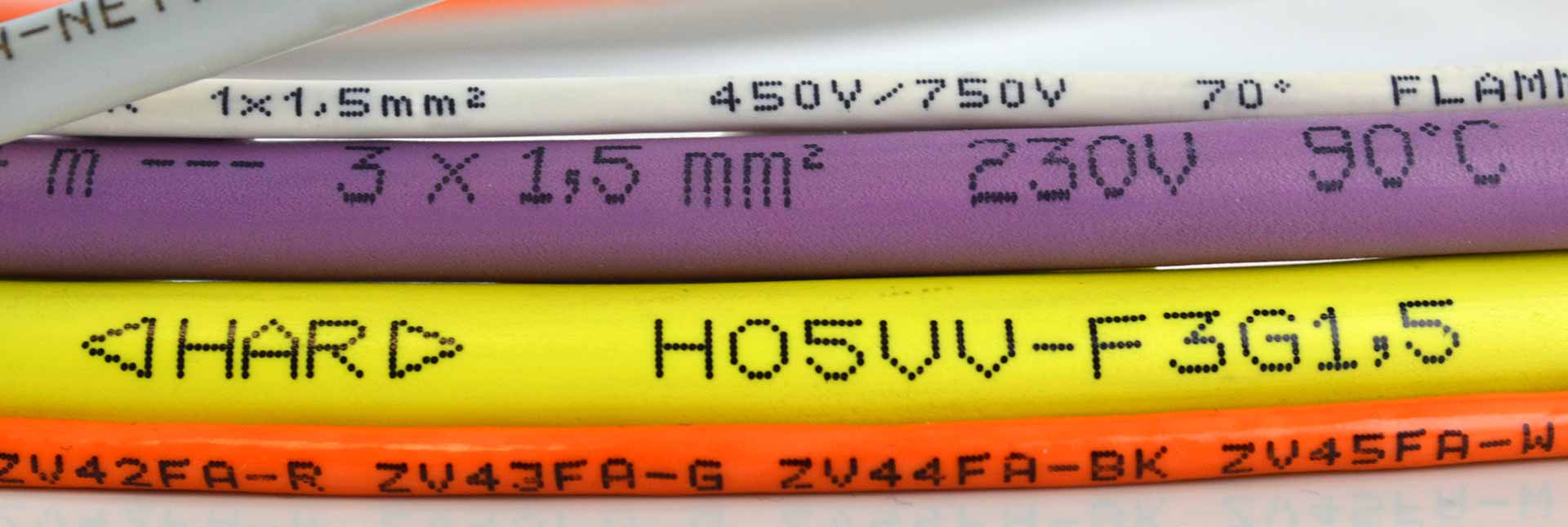

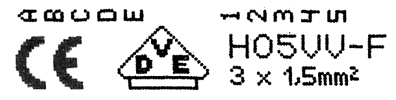

Typical wire markings

LEIBINGER printers can apply a variety of information onto wires and cables, including:

- Characters and text

- Meter marking

- Batch numbers/lot numbers

- Company logos

- 1D and 2D codes

- Good/bad marking

- Materials

How to mark electrical wires

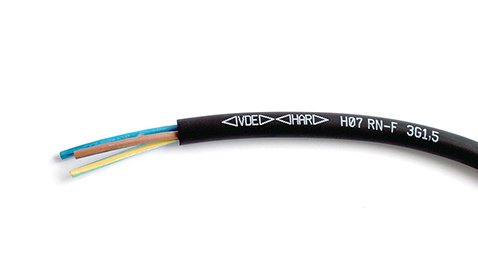

Our printers can print on a variety of wire, cable and pipe surfaces, and in a variety of different production environments. LEIBINGER gives customers with our special wire printers the flexibility to choose the perfect solution for their needs. For example, if you need to print on a dark surface, we offer the JET Rapid Wire PI, which handle pigmented ink that offer greater legibility on all kinds of materials. You can code wires legibly every time, whatever the material in use.

Automotive >>>

Wires, cables, tubes and pipes >>>

Electronic and electrical devices >>>

Metal and steel >>>

Looking for a PVC pipe inkjet printing machine?

PVC pipes are just one of a wide range of surfaces that our products handle. Others include:

- Plastics such as PE (polyethylene), PP (polypropylene), PVC (polyvinyl chloride), etc.

- Metals like iron, copper, brass, aluminum, gold, silver, stainless steel, etc.

- Synthetic rubber/natural rubber/Buna rubber (polybutadiene)

- Fiberglass cable

Further printing options

The LEIBINGER CIJ cable printers use the "Speed Dependent Output" function, for example, to control plasma pretreating (also: corona pre-handling) for cable marking and coding based on the production speed. If the production speed of the extrusion line drops below a specified value, the JET Rapid Wire or the JET3up printer automatically switches off the plasma until the line returns to a higher production speed. Production downtimes are avoid.

Examples of typical applications

- Marking and coding after extrusion or after wire drawing

- Using pigmented inks (opaque inks) on cables, pipes and tubes for high contrast marking on different colored backgrounds

- Special inks for the best durability, e.g. heat-resistant inks

- Micro-printouts, particularly small font sizes down to 0.8 mm

- Marking on the fly during very fast production speeds (high-speed meter markings)

Keep you running productively

For all applications, LEIBINGER wire markers, accessories, software and consumables bring high reliability and high speed. Whatever your wire marking requirements are, our solutions have the quality and performance to keep your production running.

A solution to suit all cable, wire or pipe widths

For wire, pipe and cable marking and coding, the option to print at small font heights (microprints) is important, as is a wide selection of inks for various colored backgrounds. We also provide comprehensive software and hardware accessories for the cable printer for easy and flexible integration into product lines, such as rereelers and cable routing systems. That all plays a crucial role in the efficiency of production. In summary, our machines can be used for all applications: they are wire markers and pipe markers. They handle any products from electrical wire, PVC pipes to tubes.

Intelligent marking technology

For the wire industry

IQJET - the world's first intelligent coding system. Elevate your wire marking capabilities to new heights with our cutting-edge technology and a maintenance-free duration of five years.