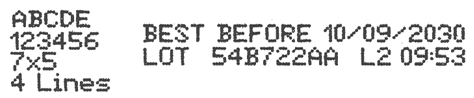

The new IQJET. The first intelligent coding & marking system.

With IQJET: Plug & print, 5 years maintenance-free and the best TCO values on the market thanks to low consumption of resources - that's what the new LEIBINGER IQJET offers. This intelligent printer ensures undisturbed, carefree work and maximum productivity in your production, because the IQJET simply does what it is supposed to: Printing, printing, printing...